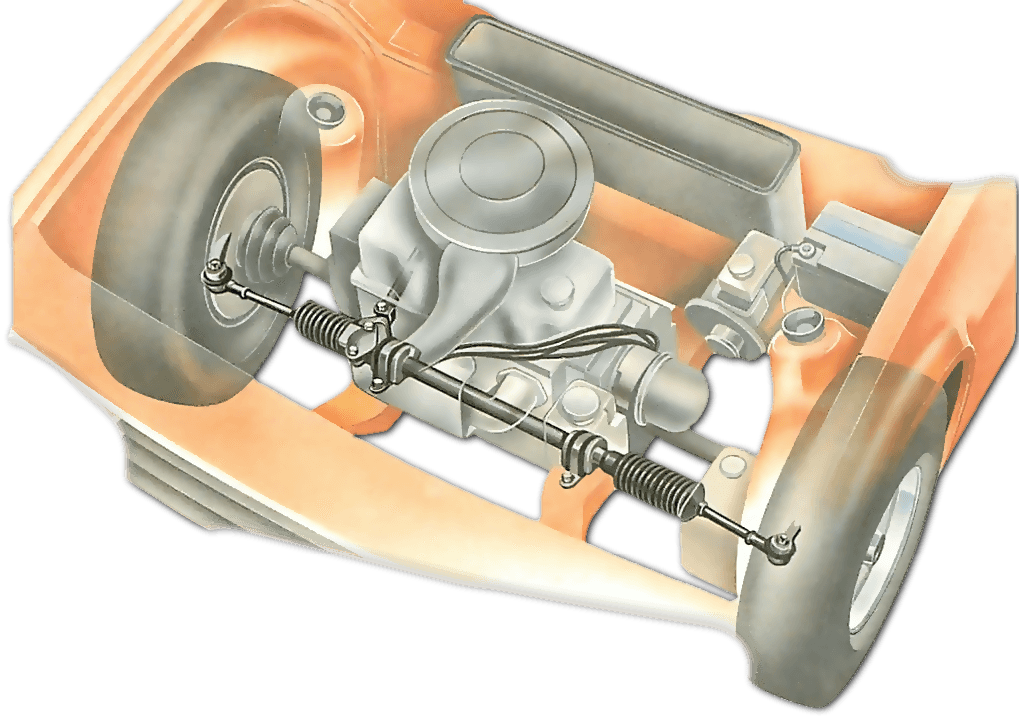

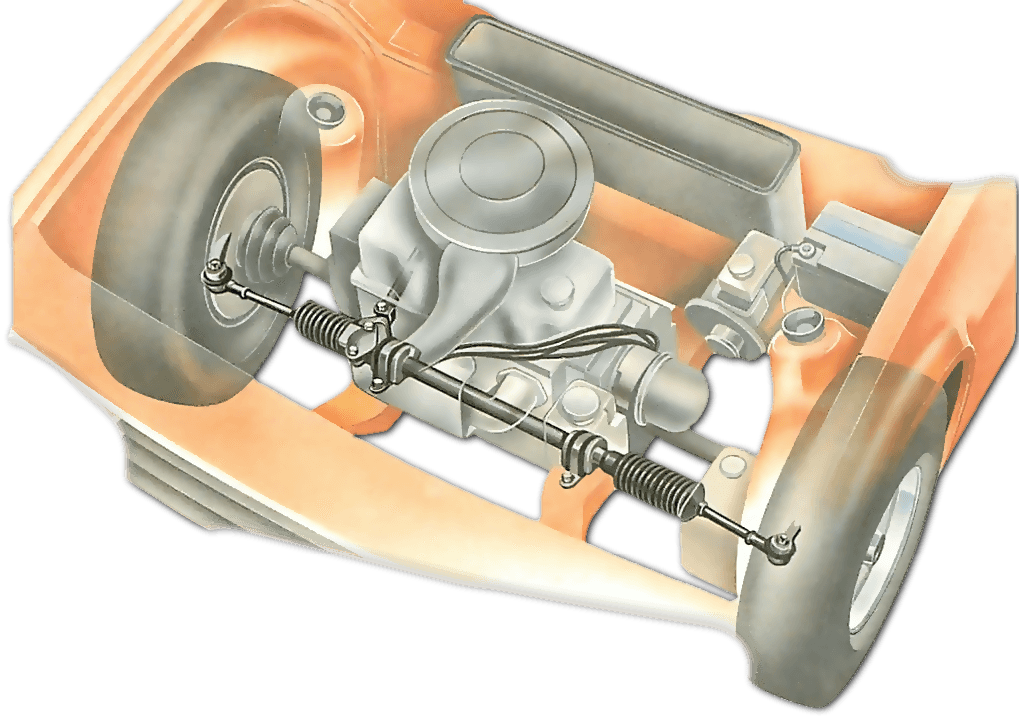

Steering machine is in the driver steering wheel at the same time, to help the driver to force, in order to reduce the driver steering with strength, to achieve the driver easy, convenient purpose of the machine. It is mainly divided into rack and pinion steering and worm wheel and worm steering. There are roughly three kinds of power steering devices on the market: electric motor power steering, rack and pinion hydraulic power steering, and electric hydraulic power steering.

Introduction Of Steering Rack

Steering engine The power steering system of the car steering energy, under normal circumstances, only a small part of the driver's energy, and most of the engine (or motor) driven oil pump (or air compressor) provided by the hydraulic energy (or pressure energy).

For the engine (or motor) output of part of the mechanical energy into pressure energy, and under the control of the driver, the steering gear or a transmission part of the application of hydraulic or pneumatic force in different directions, to help the driver force insufficient a series of parts, known as the power steering gear.

The Working Principle Of

Motor-assisted steering starts when the driver moves the steering wheel.

Rack-and-pinion power steering is a hydraulic pump on the side of the engine that drives the pump.

Electric hydraulic power is a combination of the first two and the best steering power on the market today.

The structure of the steering booster is very complex, ordinary people can not repair, usually maintenance in place, it is not easy to break. Note: you should always check the oil in the oil cup, not lower than the lower limit of the dipstick. If the booster loses oil, the pressure pump may be scrapped. Two, change the oil regularly and three, you can't shoot the direction. Four try not to hit direction in place.

Power comes from the engine, the truck has no other way to help, only hydraulic booster pump, generally installed on the flywheel housing, driven by the crankshaft hydraulic pump. There are also belts in front of the engine, but these are usually modified.

Power steering system is based on mechanical steering system and a set of power auxiliary devices. The steering pump 6 is mounted on the engine and is driven by the crankshaft through the belt and outputs hydraulic oil. Steering tank 5 has inlet and outlet tubing joints, which are connected with steering oil pump and steering control valve 2 respectively through tubing. The steering control valve is used to change the oil path. The mechanical steering device and the cylinder block form two working cavities, which are connected by oil passage and steering control valve respectively.

When the car runs in a straight line, the steering control valve 2 communicates with the oil tank the working fluid pumped out of the steering oil pump 6. The steering oil pump is in unloading state, and the power steering device does not help. When the car needs to turn right, the driver turns right to the steering wheel, the steering control valve will turn the working fluid pumped out of the steering pump and R cavity connected, the L cavity connected with the oil tank, under the action of oil pressure, the piston moves down, through the transmission structure to make the left and right wheel deflection to the right, so as to achieve right steering. When turning left, the opposite is true.

Type Of Steering Rack

According to the different energy transmission medium, the power steering device has two kinds of pneumatic and hydraulic. Pneumatic power steering gear is not suitable for trucks with large loads, because the working pressure of pneumatic system is low (generally not higher than 0.7mpa), and its component size will be too large when used in heavy vehicles. The working pressure of hydraulic power steering gear can be as high as 10MPa, so its component size is very small. The hydraulic system has no noise, short lag time, and can absorb the impact from uneven road surface. Therefore, hydraulic power steering gear has been widely used in all kinds of vehicles.

According to the mechanical steering gear, steering power cylinder and control valve in the steering gear arrangement and coupling relations between different, hydraulic power steering gear is divided into integral mechanical steering gear, steering power cylinder and control valve (the three design as a whole), compound (mechanical steering and steering control valve design together, Independent steering power cylinder) and separated (independent mechanical steering valve, steering control valve and steering power cylinder design as one) three types of structure.

Only hydraulic integral power steering gear is introduced here.

Trouble Shooting Of Steering Rack

Fault Phenomenon:

Phenomenon: Steering gear heavy.

Cause: Lack of hydraulic oil in steering system, or air in oil circuit; The filter core of the oil storage tank is blocked or the filter screen is used for too long, which is damaged and the oil outlet hole is blocked; The regulating valve on the oil pump does not work well; The sealing ring on the power piston or the sealing ring in the middle of the two radial sealing ring groove on the valve body is damaged; Poor effect of slide valve (clearance is too large or closed loosely); Check valve action (leakage) and so on will cause heavy steering. Low pump pressure of the oil pump and wear of the steering rod ball head, poor lubrication of the steering knuckle kingpin, will also cause heavy steering.

Elimination Steps:

(1) Check whether the oil level of the hydraulic oil storage tank is too low and whether there is air in the oil. If the oil level is too low, add hydraulic oil to make the oil level reach the specified height of the dipstick. If there is air in the hydraulic oil, we should carefully check whether the hydraulic oil pump inlet pipe is broken, cracked, and whether the joint is loose. After troubleshooting, the air in the hydraulic oil should be drained.

(2) Check whether the filter element in the oil storage tank is broken or damaged. If it is damaged, it should be replaced with a new filter element. If it is dirty, it should be cleaned.

(3) Check whether the pump oil flow rate of the oil pump and the function of the safety adjustment valve are good. The check method is as follows:

Install 150bar pressure gauge C and valve D on the high pressure tubing of the steering pump and steering gear. Open the valve, start the engine at idle speed, close the pressure gauge for about 5 seconds for a short time (the time should not be long to avoid overheating and damage of the oil pump), and check the pressure gauge. If the pressure of the pressure gauge reaches 130bar and does not continue to rise, it indicates that the hydraulic pump is working normally. If it is higher than 130bar, the safety valve is not allowed and should be adjusted to 130bar; If the pressure gauge pressure is lower than 130bar, it indicates that the hydraulic steering pump is worn heavily, has internal leakage, and the flow control valve and safety valve are not adjusted properly. It should be adjusted again. If the adjustment does not meet the requirements, the steering hydraulic pump should be replaced.

(4) check the slide valve to see whether its role is good. If the clearance is too large to close strict, should replace the new steering screw and slide valve.

(5) Check the sealing ring on the power piston, the middle sealing ring of the radial ring groove of the valve chamber body is good. Replace new parts if necessary. At the same time, the surface of the cylinder should be checked for damage.

(6) check whether the valve ball and seat of the one-way valve is sealed, if it is not strictly closed because of dirt pad, it should be thoroughly cleaned; If the valve body itself leads to loose closure, should be replaced with a new piece.

(7) Check the use and lubrication of the horizontal and straight rod ball head pin. If it is seriously worn, it should be replaced.

(8) Check the lubrication of steering knuckle kingpin and bushing. Due to poor lubrication, it will rust and lead to difficult steering.

Introduction Of Steering Rack

Steering engine The power steering system of the car steering energy, under normal circumstances, only a small part of the driver's energy, and most of the engine (or motor) driven oil pump (or air compressor) provided by the hydraulic energy (or pressure energy).

For the engine (or motor) output of part of the mechanical energy into pressure energy, and under the control of the driver, the steering gear or a transmission part of the application of hydraulic or pneumatic force in different directions, to help the driver force insufficient a series of parts, known as the power steering gear.

The Working Principle Of

Motor-assisted steering starts when the driver moves the steering wheel.

Rack-and-pinion power steering is a hydraulic pump on the side of the engine that drives the pump.

Electric hydraulic power is a combination of the first two and the best steering power on the market today.

The structure of the steering booster is very complex, ordinary people can not repair, usually maintenance in place, it is not easy to break. Note: you should always check the oil in the oil cup, not lower than the lower limit of the dipstick. If the booster loses oil, the pressure pump may be scrapped. Two, change the oil regularly and three, you can't shoot the direction. Four try not to hit direction in place.

Power comes from the engine, the truck has no other way to help, only hydraulic booster pump, generally installed on the flywheel housing, driven by the crankshaft hydraulic pump. There are also belts in front of the engine, but these are usually modified.

Power steering system is based on mechanical steering system and a set of power auxiliary devices. The steering pump 6 is mounted on the engine and is driven by the crankshaft through the belt and outputs hydraulic oil. Steering tank 5 has inlet and outlet tubing joints, which are connected with steering oil pump and steering control valve 2 respectively through tubing. The steering control valve is used to change the oil path. The mechanical steering device and the cylinder block form two working cavities, which are connected by oil passage and steering control valve respectively.

When the car runs in a straight line, the steering control valve 2 communicates with the oil tank the working fluid pumped out of the steering oil pump 6. The steering oil pump is in unloading state, and the power steering device does not help. When the car needs to turn right, the driver turns right to the steering wheel, the steering control valve will turn the working fluid pumped out of the steering pump and R cavity connected, the L cavity connected with the oil tank, under the action of oil pressure, the piston moves down, through the transmission structure to make the left and right wheel deflection to the right, so as to achieve right steering. When turning left, the opposite is true.

Type Of Steering Rack

According to the different energy transmission medium, the power steering device has two kinds of pneumatic and hydraulic. Pneumatic power steering gear is not suitable for trucks with large loads, because the working pressure of pneumatic system is low (generally not higher than 0.7mpa), and its component size will be too large when used in heavy vehicles. The working pressure of hydraulic power steering gear can be as high as 10MPa, so its component size is very small. The hydraulic system has no noise, short lag time, and can absorb the impact from uneven road surface. Therefore, hydraulic power steering gear has been widely used in all kinds of vehicles.

According to the mechanical steering gear, steering power cylinder and control valve in the steering gear arrangement and coupling relations between different, hydraulic power steering gear is divided into integral mechanical steering gear, steering power cylinder and control valve (the three design as a whole), compound (mechanical steering and steering control valve design together, Independent steering power cylinder) and separated (independent mechanical steering valve, steering control valve and steering power cylinder design as one) three types of structure.

Only hydraulic integral power steering gear is introduced here.

Trouble Shooting Of Steering Rack

Fault Phenomenon:

Phenomenon: Steering gear heavy.

Cause: Lack of hydraulic oil in steering system, or air in oil circuit; The filter core of the oil storage tank is blocked or the filter screen is used for too long, which is damaged and the oil outlet hole is blocked; The regulating valve on the oil pump does not work well; The sealing ring on the power piston or the sealing ring in the middle of the two radial sealing ring groove on the valve body is damaged; Poor effect of slide valve (clearance is too large or closed loosely); Check valve action (leakage) and so on will cause heavy steering. Low pump pressure of the oil pump and wear of the steering rod ball head, poor lubrication of the steering knuckle kingpin, will also cause heavy steering.

Elimination Steps:

(1) Check whether the oil level of the hydraulic oil storage tank is too low and whether there is air in the oil. If the oil level is too low, add hydraulic oil to make the oil level reach the specified height of the dipstick. If there is air in the hydraulic oil, we should carefully check whether the hydraulic oil pump inlet pipe is broken, cracked, and whether the joint is loose. After troubleshooting, the air in the hydraulic oil should be drained.

(2) Check whether the filter element in the oil storage tank is broken or damaged. If it is damaged, it should be replaced with a new filter element. If it is dirty, it should be cleaned.

(3) Check whether the pump oil flow rate of the oil pump and the function of the safety adjustment valve are good. The check method is as follows:

Install 150bar pressure gauge C and valve D on the high pressure tubing of the steering pump and steering gear. Open the valve, start the engine at idle speed, close the pressure gauge for about 5 seconds for a short time (the time should not be long to avoid overheating and damage of the oil pump), and check the pressure gauge. If the pressure of the pressure gauge reaches 130bar and does not continue to rise, it indicates that the hydraulic pump is working normally. If it is higher than 130bar, the safety valve is not allowed and should be adjusted to 130bar; If the pressure gauge pressure is lower than 130bar, it indicates that the hydraulic steering pump is worn heavily, has internal leakage, and the flow control valve and safety valve are not adjusted properly. It should be adjusted again. If the adjustment does not meet the requirements, the steering hydraulic pump should be replaced.

(4) check the slide valve to see whether its role is good. If the clearance is too large to close strict, should replace the new steering screw and slide valve.

(5) Check the sealing ring on the power piston, the middle sealing ring of the radial ring groove of the valve chamber body is good. Replace new parts if necessary. At the same time, the surface of the cylinder should be checked for damage.

(6) check whether the valve ball and seat of the one-way valve is sealed, if it is not strictly closed because of dirt pad, it should be thoroughly cleaned; If the valve body itself leads to loose closure, should be replaced with a new piece.

(7) Check the use and lubrication of the horizontal and straight rod ball head pin. If it is seriously worn, it should be replaced.

(8) Check the lubrication of steering knuckle kingpin and bushing. Due to poor lubrication, it will rust and lead to difficult steering.