A mixture of gasoline and air burned in a car engine.The gasoline is pumped down a pipe from the tank and mixed with air in the carburetor, from which the engine draws the mixture.

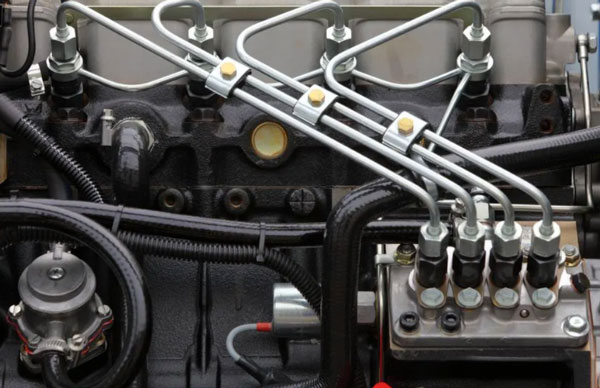

In fuel injection systems used on some engines, gasoline and air are mixed in the intake manifold.

A fuel pump is piped to draw the carburetor outside the gasoline can.

The pump may be a mechanical engine operation - or it may be electric, in this case usually beside or even inside the tank.

Keeping the petrol tank safe

To be safe, the petrol tank is at the opposite end of the car from the engine.

A float inside the tank transmits current through an electronic transmitter unit to the fuel gauge to indicate how much gasoline is in the tank.

A tank has a vent - usually a small hole in a pipe or filler cap to allow air to enter when the tank is empty.Some of the latest systems have carbon filters, so fuel fumes do not escape.

How a mechanical pump works

A Mechanical fuel pump is driven by a camshaft, or by a special shaft driven by the crankshaft.As the shaft rotates, the CAM passes under the pivot bar and pushes it up at one end.

The other end of the lever is loosely connected to a rubber diaphragm that forms the bottom of the pump chamber, and the other end descends and pulls on the diaphragm with it.

As the lever pulls the diaphragm down, it creates a suction that pulls fuel up the fuel line through the check valve into the pump.

As the rotating CAM rotates further so that it is no longer pressed on the lever, the lever moves backwards through the return spring, loosening its pull on the diaphragm.

The lever that loosens the connection does not push the diaphragm upward, but a return spring pushes the diaphragm upward.

The diaphragm can only move upward by draining the gasoline from the room.The gasoline cannot be returned through the first check valve, so it is discharged through another valve leading to the carburetor.