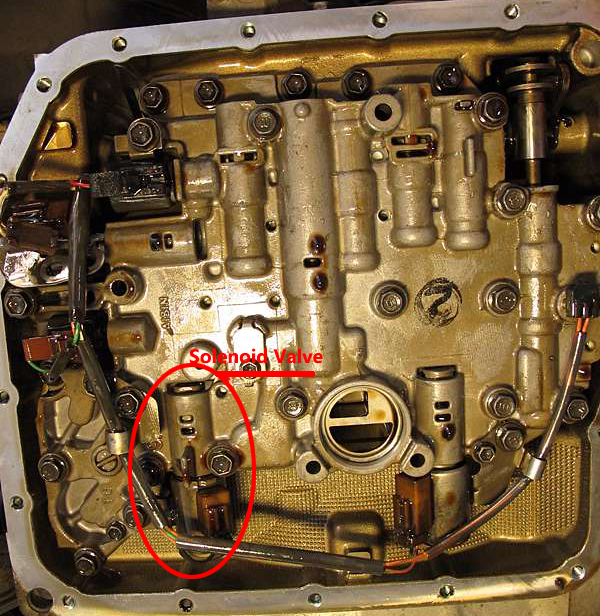

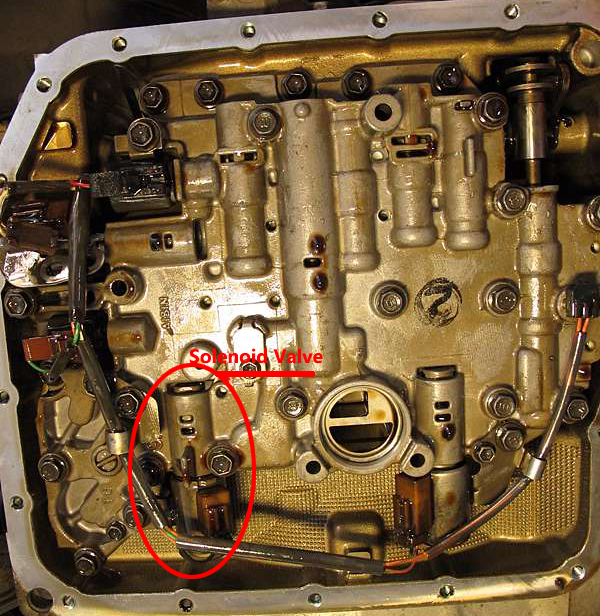

Before we know the judging automatic transmission solenoid valve inspection, detection of electromagnetic valve of method is: first to the electromagnetic valve controlled media (liquid, gas, air pressure, the pressure value used for electromagnetic valve pressure range of intermediate value), then to the solenoid coil electricity, if be controlled medium from sense to break or from off to on the change of the state, then the electromagnetic valve It's good, otherwise it's problematic. But sometimes it is not the solenoid valve, but other factors cause the solenoid valve failure, how should we deal with it?

1. The Solenoid Valve Does Not Work After It Is Energized

Check whether the power connection is bad → Reconnect and connect the connector

Check whether the power supply voltage is within the range of + Working -→ Adjusting to normal position

Whether the coil is de-welding → Rewelding

Coil short circuit → Replace coil

Whether the working pressure difference is inappropriate - Adjust the pressure difference - Or replace the appropriate solenoid valve

Fluid temperature is too high → Replace the solenoid valve commensurate

There are impurities to make the solenoid valve's main spool and moving core stuck → Cleaning, such as seal damage should replace the seal and install filter

The liquid viscosity is too large, the frequency is too high and the life has reached a liquid oil product replacement

2. The Solenoid Valve Can Not Be Closed

The seals of the main spool or iron moving core have been damaged → Replace the seals

Whether the temperature and viscosity of the fluid are too high → Replace the solenoid valve of the counterpart

There are impurities into the solenoid valve production spool or moving iron core - Cleaning

Spring life has arrived or deformation → Replacement

Choke hole balance hole blockage, timely cleaning

The working frequency is too high or the life has reached → Change the product or update the product

3. Solenoid Valve Leakage

Internal leakage → Check whether the seal is damaged and whether the spring is poorly assembled

External leakage → The joint is loose or the seal is bad → Tighten the screw or replace the seal

When energized, there is noise → Loose strong parts on the head and tight lime. Voltage fluctuation is not allowed, adjust the voltage. Iron core suction surface impurities or uneven, timely cleaning or replacement.

Solenoid Valve Common Fault Check And Treatment Method

1, Solenoid Valve Coil Short Circuit Or Break:

Detection method: first use a multimeter to measure its on and off, resistance value tends to zero or infinity, it shows that the coil short circuit or open. If measure the normal (probably dozens of Europe), also can't explain the coil must be good (I once measured a solenoid coil about 50 ohm resistance value, but the electromagnetic valve can't action, replace the coil after everything is normal), please to the ultimate test as follows: to find a small screwdriver on wear near a metal rod in electromagnetic valve coil, and then to the solenoid valve electricity, if Feel magnetic, then the solenoid valve coil is good, otherwise it is bad. Solution: Replace the solenoid valve coil.

2, Solenoid Valve Plug/Socket Problems:

Fault symptoms:

If the solenoid valve is the kind of plug/socket, there may be metal reed problems in the socket, plug wiring problems (such as connecting the power line to the ground line) and other reasons can not send power to the coil. It's best to get in the habit of putting the plug in the socket and the screw in the coil behind the spool.

If the plug of the solenoid valve coil is equipped with a light-emitting diode power indicator, then the use of DC power supply to drive the solenoid valve is connected to the line, otherwise the indicator will not be on. In addition, do not switch the power plug with the LED power indicator at different voltage levels, as this will cause the LED to be burnt/the power supply (switch to a lower voltage level plug) will short-circuit or the LED will emit very weak light (switch to a higher voltage level plug).

If there is no power indicator, the solenoid valve coil is not to distinguish polarity (unlike the transistor time relay whose coil voltage is DC and the intermediate relay whose coil voltage is DC in parallel with the diode/resistor leakage loop on the coil. This intermediate relay is in the majority of the original Japanese, which needs to distinguish polarity).

Solution: correct wiring errors, repair or replace the plug, socket.

Solenoid valve controlling variable timing system

3, Solenoid Valve Spool Problem:

Fault phenomenon 1: in the case of normal pressure of the solenoid valve through medium, press the manual button of the solenoid valve red, the solenoid valve does not have any reaction (pressure medium does not appear on and off changes), that the spool must be bad.

Treatment method: check whether there is a problem with the medium, such as whether there is a lot of water in the compressed air (sometimes the role of the oil-water separator is not very big, especially when the pipeline design is poor when the compressed air to the solenoid valve will have a lot of water), whether there are a lot of impurities in the liquid medium. Then remove water or impurities in the solenoid valve and pipeline. If not, please repair or replace the spool, or simply replace the whole solenoid valve.

Fault phenomenon 2: after inspection, the coil is the original coil and the coil is energized when the magnetic is normal, but the solenoid valve still does not work (then the solenoid valve manual button function may be normal), indicating that the spool is bad.

Treatment: please repair or replace the spool, or simply replace the whole solenoid valve.

Conclusion

Above for electromagnetic valve common faults and processing methods, can be a reference when we repair cars, now generally within the transmission solenoid valve malfunction generally change all the electromagnetic valve, so that the greatest degree of avoid failure, the solenoid valve greatly guarantee the quality of the auto transmission after repair.

1. The Solenoid Valve Does Not Work After It Is Energized

Check whether the power connection is bad → Reconnect and connect the connector

Check whether the power supply voltage is within the range of + Working -→ Adjusting to normal position

Whether the coil is de-welding → Rewelding

Coil short circuit → Replace coil

Whether the working pressure difference is inappropriate - Adjust the pressure difference - Or replace the appropriate solenoid valve

Fluid temperature is too high → Replace the solenoid valve commensurate

There are impurities to make the solenoid valve's main spool and moving core stuck → Cleaning, such as seal damage should replace the seal and install filter

The liquid viscosity is too large, the frequency is too high and the life has reached a liquid oil product replacement

2. The Solenoid Valve Can Not Be Closed

The seals of the main spool or iron moving core have been damaged → Replace the seals

Whether the temperature and viscosity of the fluid are too high → Replace the solenoid valve of the counterpart

There are impurities into the solenoid valve production spool or moving iron core - Cleaning

Spring life has arrived or deformation → Replacement

Choke hole balance hole blockage, timely cleaning

The working frequency is too high or the life has reached → Change the product or update the product

3. Solenoid Valve Leakage

Internal leakage → Check whether the seal is damaged and whether the spring is poorly assembled

External leakage → The joint is loose or the seal is bad → Tighten the screw or replace the seal

When energized, there is noise → Loose strong parts on the head and tight lime. Voltage fluctuation is not allowed, adjust the voltage. Iron core suction surface impurities or uneven, timely cleaning or replacement.

Solenoid Valve Common Fault Check And Treatment Method

1, Solenoid Valve Coil Short Circuit Or Break:

Detection method: first use a multimeter to measure its on and off, resistance value tends to zero or infinity, it shows that the coil short circuit or open. If measure the normal (probably dozens of Europe), also can't explain the coil must be good (I once measured a solenoid coil about 50 ohm resistance value, but the electromagnetic valve can't action, replace the coil after everything is normal), please to the ultimate test as follows: to find a small screwdriver on wear near a metal rod in electromagnetic valve coil, and then to the solenoid valve electricity, if Feel magnetic, then the solenoid valve coil is good, otherwise it is bad. Solution: Replace the solenoid valve coil.

2, Solenoid Valve Plug/Socket Problems:

Fault symptoms:

If the solenoid valve is the kind of plug/socket, there may be metal reed problems in the socket, plug wiring problems (such as connecting the power line to the ground line) and other reasons can not send power to the coil. It's best to get in the habit of putting the plug in the socket and the screw in the coil behind the spool.

If the plug of the solenoid valve coil is equipped with a light-emitting diode power indicator, then the use of DC power supply to drive the solenoid valve is connected to the line, otherwise the indicator will not be on. In addition, do not switch the power plug with the LED power indicator at different voltage levels, as this will cause the LED to be burnt/the power supply (switch to a lower voltage level plug) will short-circuit or the LED will emit very weak light (switch to a higher voltage level plug).

If there is no power indicator, the solenoid valve coil is not to distinguish polarity (unlike the transistor time relay whose coil voltage is DC and the intermediate relay whose coil voltage is DC in parallel with the diode/resistor leakage loop on the coil. This intermediate relay is in the majority of the original Japanese, which needs to distinguish polarity).

Solution: correct wiring errors, repair or replace the plug, socket.

Solenoid valve controlling variable timing system

3, Solenoid Valve Spool Problem:

Fault phenomenon 1: in the case of normal pressure of the solenoid valve through medium, press the manual button of the solenoid valve red, the solenoid valve does not have any reaction (pressure medium does not appear on and off changes), that the spool must be bad.

Treatment method: check whether there is a problem with the medium, such as whether there is a lot of water in the compressed air (sometimes the role of the oil-water separator is not very big, especially when the pipeline design is poor when the compressed air to the solenoid valve will have a lot of water), whether there are a lot of impurities in the liquid medium. Then remove water or impurities in the solenoid valve and pipeline. If not, please repair or replace the spool, or simply replace the whole solenoid valve.

Fault phenomenon 2: after inspection, the coil is the original coil and the coil is energized when the magnetic is normal, but the solenoid valve still does not work (then the solenoid valve manual button function may be normal), indicating that the spool is bad.

Treatment: please repair or replace the spool, or simply replace the whole solenoid valve.

Conclusion

Above for electromagnetic valve common faults and processing methods, can be a reference when we repair cars, now generally within the transmission solenoid valve malfunction generally change all the electromagnetic valve, so that the greatest degree of avoid failure, the solenoid valve greatly guarantee the quality of the auto transmission after repair.