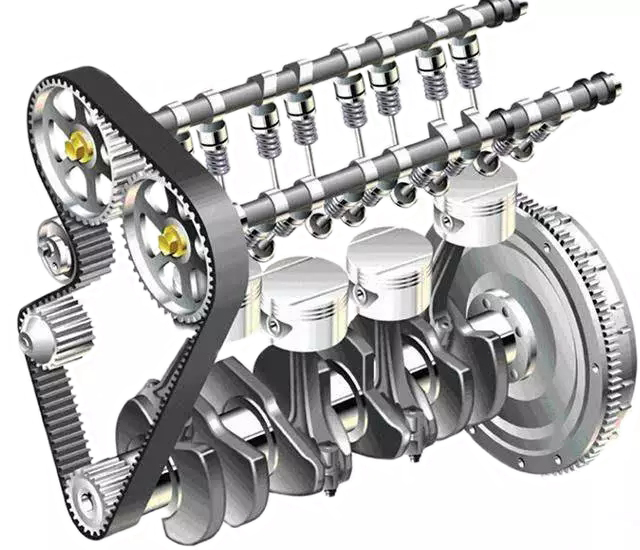

The Engine Piston Movement Process Is:

1. The piston moves from BDC to BDC under the drive of the crankshaft. The intake valve opens and the exhaust valve closes. A mixture of air and gasoline is drawn into the cylinder through the intake valve and further mixed in the cylinder to form a combustible mixture.

2. Close the intake and exhaust valves at the same time. The piston moves from BDC to TDC, and the pressure and temperature of the mixture in the cylinder rise continuously after being compressed.

3. The intake and exhaust valves are closed at the same time. When the piston approaches TDC, the spark plug ignits the combustible mixture, which releases a lot of heat energy. The high temperature and high pressure gas pushes the piston to move from TDC to TDC, and outputs the mechanical energy externally through the crank connecting rod mechanism.

4. The exhaust valve is opened, the intake valve is closed, the piston moves from BDC to TDC, and the exhaust gas after combustion is discharged to the cylinder under the action of pressure difference between inside and outside the cylinder.

The piston of automobile engine is one of the main parts of the engine. It forms a piston group with piston ring, piston pin and other parts, and forms a combustion chamber together with the cylinder head. It bears the gas force and passes the power to the crankshaft through the piston pin and connecting rod to complete the working process of the internal combustion engine. Because the piston in a high speed, high pressure and high temperature of bad working environment, and to take into account the engine running smooth and durable, so the piston also must want to have enough strength and rigidity, good thermal conductivity, high thermal stability, small expansion coefficient, size and shape change smaller) (small relative density (light weight), wear resistance and corrosion resistance, and low cost.

Because of the many and high requirements, some of which are contradictory, it is difficult to find a piston material that can fully meet the requirements. The piston of modern engine is generally made of aluminum alloy, because aluminum alloy material has the outstanding advantages of small density and good thermal conductivity, but at the same time, it has the disadvantages of relatively large expansion coefficient and poor high temperature strength. These disadvantages can only be satisfied by reasonable structural design. Therefore, the quality of the car engine, not only to see the use of materials, but also to see the rationality of the design.

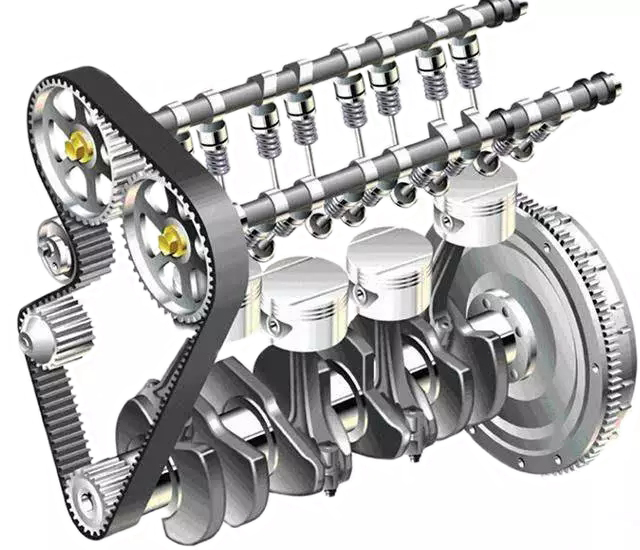

1. The piston moves from BDC to BDC under the drive of the crankshaft. The intake valve opens and the exhaust valve closes. A mixture of air and gasoline is drawn into the cylinder through the intake valve and further mixed in the cylinder to form a combustible mixture.

2. Close the intake and exhaust valves at the same time. The piston moves from BDC to TDC, and the pressure and temperature of the mixture in the cylinder rise continuously after being compressed.

3. The intake and exhaust valves are closed at the same time. When the piston approaches TDC, the spark plug ignits the combustible mixture, which releases a lot of heat energy. The high temperature and high pressure gas pushes the piston to move from TDC to TDC, and outputs the mechanical energy externally through the crank connecting rod mechanism.

4. The exhaust valve is opened, the intake valve is closed, the piston moves from BDC to TDC, and the exhaust gas after combustion is discharged to the cylinder under the action of pressure difference between inside and outside the cylinder.

The piston of automobile engine is one of the main parts of the engine. It forms a piston group with piston ring, piston pin and other parts, and forms a combustion chamber together with the cylinder head. It bears the gas force and passes the power to the crankshaft through the piston pin and connecting rod to complete the working process of the internal combustion engine. Because the piston in a high speed, high pressure and high temperature of bad working environment, and to take into account the engine running smooth and durable, so the piston also must want to have enough strength and rigidity, good thermal conductivity, high thermal stability, small expansion coefficient, size and shape change smaller) (small relative density (light weight), wear resistance and corrosion resistance, and low cost.

Because of the many and high requirements, some of which are contradictory, it is difficult to find a piston material that can fully meet the requirements. The piston of modern engine is generally made of aluminum alloy, because aluminum alloy material has the outstanding advantages of small density and good thermal conductivity, but at the same time, it has the disadvantages of relatively large expansion coefficient and poor high temperature strength. These disadvantages can only be satisfied by reasonable structural design. Therefore, the quality of the car engine, not only to see the use of materials, but also to see the rationality of the design.