When the technical condition of the automobile transmission shaft deteriorates, the amplitude of the bending vibration increases, the vibration is severe, and even causes the body shaking, and gives out obvious periodic sound, which is called shaking and abnormal sound. Automobile drive shaft increases with the increase of speed, drive shaft vibration and abnormal sound of the main group has the following aspects.

1. Drive Shaft Assembly Is Out Of Balance

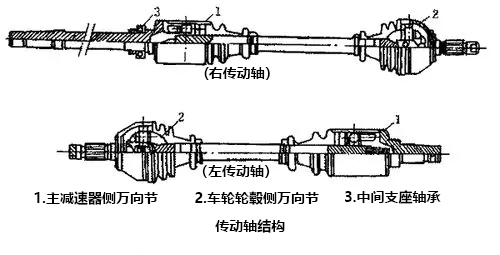

The assembly error of the transmission shaft assembly is beyond the limit, the size of the parts is not accurate and the wear and deformation in use will make the mass distribution of the transmission shaft along the length direction is not uniform and cause the transmission imbalance. Unbalanced transmission shaft in operation will produce additional bending moment, the role of additional bending moment will not only make the impact of the fitting ring, but also enhance the bending vibration of the transmission shaft, so that the vibration of the transmission shaft and abnormal sound more obvious.

2. Universal Joint Damage

The main damage of universal joint in use is wear of cross shaft journal and end face and wear of needle roller and bearing seat hole. The damage of universal joint parts makes the cross shaft with loose and loose and produce swing and axial movement, not only in the work of a crash, but also weaken the bending stiffness of the transmission shaft. The center of mass of the drive shaft is further away from the axis of rotation, thus enhancing the vibration and abnormal sound.

3. Drive Shaft And Sliding Fork Damage

Transmission shaft tube bending, that is, increase the amplitude of transmission shaft bending vibration, can increase the centrifugal force, resulting in strong vibration and abnormal sound. Drive shaft key teeth and sliding fork keyway wear, due to loose coordination, will make a sound in the work, but also weaken the bending stiffness of the drive shaft, enhance vibration and abnormal sound.

4. The Installation Position Of Both Ends Of The Drive Shaft Is Changed

For a universal joint drive shaft with unequal angular velocity, the following two conditions must be met in order to reduce the vibration of the drive shaft and ensure uniform rotation of the drive axle gear:

1) Universal joint forks at both ends of the transmission shaft should be located in the same plane;

2) The Angle between the input shaft, output shaft and the drive shaft should be equal. Drive shaft in use, because of drive shaft key tooth and sliding fork keyway wear, universal joint cross shaft journal and roller needle loose, etc., will make the first condition damage; The second condition will be damaged due to the bad installation of the drive shaft, the change of the technical condition of the elastic suspension and the change of the installation position caused by the wear of the input shaft and output shaft of the drive shaft. With the destruction of constant speed transmission conditions, the main reduction gear of the drive axle will impact, and cause the instability of the drive shaft operation, enhance the jitter and abnormal sound.

5. The Critical Speed Of The Transmission Shaft Is Reduced

The maximum speed of the drive shaft is usually 0.7 times the critical speed. However, due to the damage of the dynamic balance of the transmission shaft, the damage of the universal joint and the loose middle support bearing, the critical speed of the transmission shaft will be reduced. When the critical speed is reduced to the speed of the drive shaft, the drive shaft is easy to produce resonance in operation. When the transmission shaft resonance amplitude is the largest, the vibration is violent, which often causes the transmission shaft to break.

1. Drive Shaft Assembly Is Out Of Balance

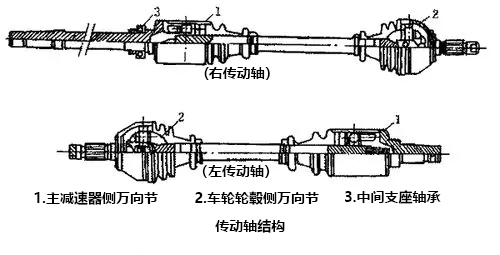

The assembly error of the transmission shaft assembly is beyond the limit, the size of the parts is not accurate and the wear and deformation in use will make the mass distribution of the transmission shaft along the length direction is not uniform and cause the transmission imbalance. Unbalanced transmission shaft in operation will produce additional bending moment, the role of additional bending moment will not only make the impact of the fitting ring, but also enhance the bending vibration of the transmission shaft, so that the vibration of the transmission shaft and abnormal sound more obvious.

2. Universal Joint Damage

The main damage of universal joint in use is wear of cross shaft journal and end face and wear of needle roller and bearing seat hole. The damage of universal joint parts makes the cross shaft with loose and loose and produce swing and axial movement, not only in the work of a crash, but also weaken the bending stiffness of the transmission shaft. The center of mass of the drive shaft is further away from the axis of rotation, thus enhancing the vibration and abnormal sound.

3. Drive Shaft And Sliding Fork Damage

Transmission shaft tube bending, that is, increase the amplitude of transmission shaft bending vibration, can increase the centrifugal force, resulting in strong vibration and abnormal sound. Drive shaft key teeth and sliding fork keyway wear, due to loose coordination, will make a sound in the work, but also weaken the bending stiffness of the drive shaft, enhance vibration and abnormal sound.

4. The Installation Position Of Both Ends Of The Drive Shaft Is Changed

For a universal joint drive shaft with unequal angular velocity, the following two conditions must be met in order to reduce the vibration of the drive shaft and ensure uniform rotation of the drive axle gear:

1) Universal joint forks at both ends of the transmission shaft should be located in the same plane;

2) The Angle between the input shaft, output shaft and the drive shaft should be equal. Drive shaft in use, because of drive shaft key tooth and sliding fork keyway wear, universal joint cross shaft journal and roller needle loose, etc., will make the first condition damage; The second condition will be damaged due to the bad installation of the drive shaft, the change of the technical condition of the elastic suspension and the change of the installation position caused by the wear of the input shaft and output shaft of the drive shaft. With the destruction of constant speed transmission conditions, the main reduction gear of the drive axle will impact, and cause the instability of the drive shaft operation, enhance the jitter and abnormal sound.

5. The Critical Speed Of The Transmission Shaft Is Reduced

The maximum speed of the drive shaft is usually 0.7 times the critical speed. However, due to the damage of the dynamic balance of the transmission shaft, the damage of the universal joint and the loose middle support bearing, the critical speed of the transmission shaft will be reduced. When the critical speed is reduced to the speed of the drive shaft, the drive shaft is easy to produce resonance in operation. When the transmission shaft resonance amplitude is the largest, the vibration is violent, which often causes the transmission shaft to break.