What are the components of a car cooling system?

What is a Cooling System?

A typical 4 cylinder vehicle cruising along the highway at around 50 miles per hour will produce 4,000 controlled explosions per minute inside the engine as the spark plugs ignite the fuel in each cylinder to propel the vehicle down the road. Obviously, these explosions produce an enormous amount of heat and, if not controlled, will destroy an engine in a matter of minutes. Controlling these high temperatures is the job of the cooling system.

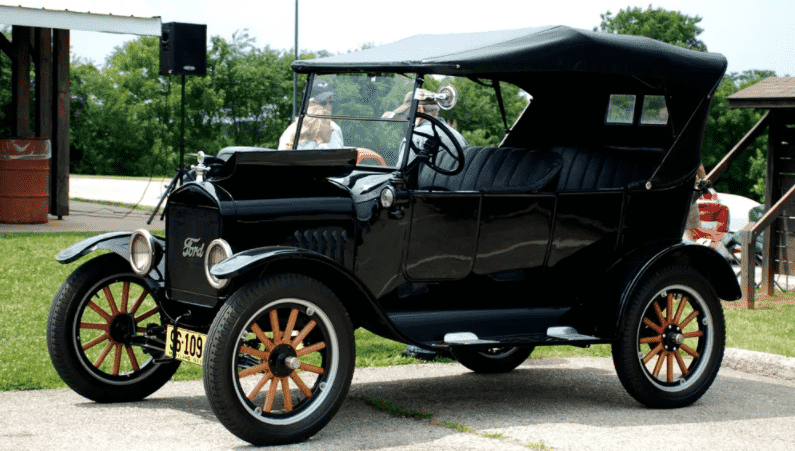

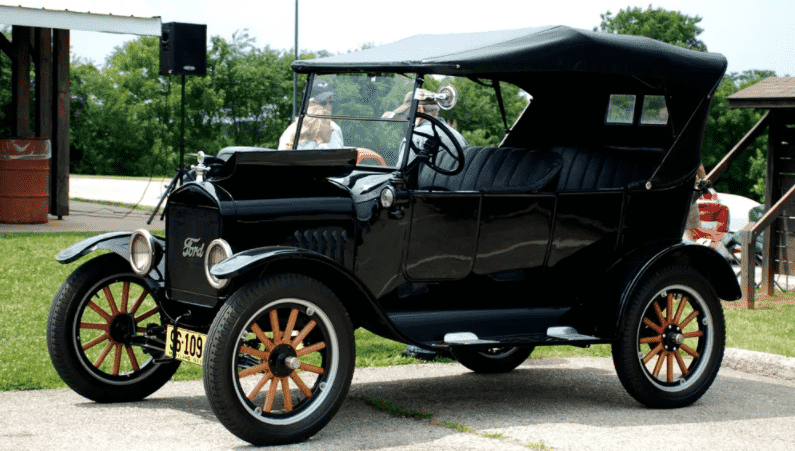

The modern cooling system has not changed much from the cooling systems in the model T back in the ’20s. Oh sure, it has become infinitely more reliable and efficient at doing its job, but the basic cooling system still consists of liquid coolant being circulated through the engine, then out to the radiator to be cooled by the air stream coming through the front grill of the vehicle.

Today’s cooling system must maintain the engine at a constant temperature whether the outside air temperature is 110 degrees Fahrenheit or 10 below zero. If the engine temperature is too low, fuel economy will suffer and emissions will rise. If the temperature is allowed to get too hot for too long, the engine will self destruct.

The Components of a Cooling System

The Radiator

Radiator Cooling Fans

Pressure Cap & Reserve Tank

Water Pump

Thermostat

Bypass System

Freeze Plugs

Head Gaskets & Intake Manifold Gaskets

Heater Core

Hoses

Radiator

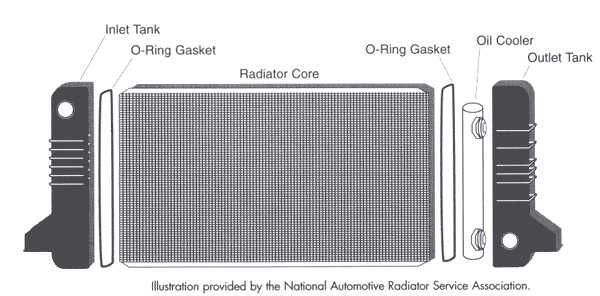

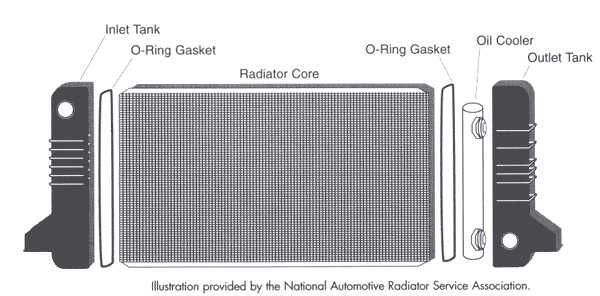

The radiator core is usually made up of flattened aluminum tubes with aluminum strips that zigzag between the tubes. These fins transfer the heat in the tubes to the air stream, to be carried away from the vehicle. On each end of the radiator core is a tank, usually made of plastic, that covers the ends of the radiator.

On most modern radiators, the tubes run horizontally with the plastic tank on either side. On other cars, the tubes run vertically with the tank on the top and bottom.

On older vehicles, the core was made of copper and the tanks were brass. The new aluminum-plastic system is much more efficient, not to mention cheaper to produce.

On radiators with plastic end caps, there are gaskets between the aluminum core and the plastic tanks to seal the system and keep the fluid from leaking out. On older copper and brass radiators, the tanks were brazed (a form of welding) in order to seal the radiator.

The tanks, whether plastic or brass, each have a large hose connection. One is mounted towards the top of the radiator to let the coolant in while the other is mounted at the bottom of the radiator on the other tank to let the coolant back out.

On top of the radiator is an additional opening that is capped off by the radiator cap (more on this later).

Another component in the radiator for vehicles with an automatic transmission is a separate tank mounted inside one of the tanks. Fittings connect this inner tank through steel tubes to the automatic transmission. Transmission fluid is piped through this tank inside a tank to be cooled by the coolant flowing past it before returning the the transmission.

Radiator Fans

Mounted on the back of the radiator, on the side closest to the engine, is one or two electric fans inside a housing that is designed to protect fingers and to direct air flow. These fans are there to keep the air flow going through the radiator while the vehicle is slowing down or when it’s stopped with the engine running. If these fans stopped working, every time you came to a stop, the engine temperature would begin rising.

On older systems, the fan was connected to the front of the water pump and would spin whenever the engine was running because it was driven by a fan belt instead of an electric motor. In these cases, if a driver would notice the engine begin to run hot in stop and go driving, the driver might put the car in neutral and rev the engine to turn the fan faster which helped cool the engine. Racing the engine on a car with a malfunctioning electric fan would only make things worse because you are producing more heat in the radiator with no fan to cool it off.

The electric fans are controlled by the vehicle’s computer. A temperature sensor monitors engine temperature and sends this information to the computer. The latter determines if the fan should be turned on and actuates the fan relay if additional air flow through the radiator is necessary.

If the car has air conditioning, there is an additional radiator mounted in front of the normal radiator. This “radiator” is called the air conditioner condenser, which also needs to be cooled by the air flow entering the engine compartment. You can find out more about the air conditioning condenser by going to our article on Automotive Air Conditioning.

As long as the air conditioning is turned on, the system will keep the fan running, even if the engine is not running hot. This is because if there is no air flow through the air conditioning condenser, the air conditioner will not be able to cool the air entering the interior.

Having a bad condenser will usually result in your air conditioning not being as cold as it should be, or it won’t even work at all.

Water Pump

A water pump is a simple device that will keep the coolant moving as long as the engine is running. It is usually mounted on the front of the engine and turns whenever the engine is running. The water pump is driven by the engine through one of the following:

A fan belt that will also be responsible for driving an additional component like an alternator or power steering pump

A serpentine belt, which also drives the alternator, power steering pump, and AC compressor among other things

The timing belt, which is also responsible for driving one or more camshafts

The water pump is made up of a housing, usually made of cast iron or cast aluminum and an impeller mounted on a spinning shaft with a pulley attached to the shaft on the outside of the pump body.

A seal keeps fluid from leaking out of the pump housing past the spinning shaft. The impeller uses centrifugal force to draw the coolant in from the lower radiator hose and send it under pressure into the engine block. There is a gasket to seal the water pump to the engine block and prevent the flowing coolant from leaking out where the pump is attached to the block.

Thermostat

The thermostat is simply a valve that measures the temperature of the coolant and, if it is hot enough, opens to allow the coolant to flow through the radiator. If the coolant is not hot enough, the flow to the radiator is blocked and fluid is directed to a bypass system that allows the coolant to return to the engine. This bypass system allows the coolant to keep moving through the engine to balance the temperature and avoid hot spots. Because flow to the radiator is blocked, the engine will reach operating temperature sooner and, on a cold day, will allow the heater to begin supplying hot air to the interior more quickly.

The heart of a thermostat is a sealed copper cup that contains wax and a metal pellet. As the thermostat heats up, the hot wax expands, pushing a piston against spring pressure to open the valve and allow coolant to circulate.

The thermostat is usually located in the front, top part of the engine in a water outlet housing that also serves as the connection point for the upper radiator hose. Its housing attaches to the engine, usually with two bolts and a gasket to seal it against leaks. This gasket is usually made of a heavy paper, or uses a rubber O-ring. In some applications, there is no gasket or rubber seal. Instead, a thin bead of special silicone sealer is squeezed from a tube to form a seal.

There is a mistaken belief by some people that if they remove the thermostat, they will be able to solve hard to find overheating problems—but this couldn’t be further from the truth. Removing the thermostat will allow uncontrolled circulation of the coolant throughout the system. It is possible for the coolant to move so fast that it will not be properly cooled as it races through the radiator, so the engine can run even hotter than before under certain conditions.

Other times, the engine will never reach its operating temperature. On computer controlled vehicles, the computer monitors engine temperatures and regulates fuel usage based on that temperature. If the engine never reaches operating temperatures, fuel economy and performance will suffer considerably.

Head Gaskets and Intake Manifold Gaskets

All internal combustion engines have an engine block and one or two cylinder heads. The mating surfaces where the block and head meet are machined flat for a close, precise fit, but no amount of careful machining will allow them to be completely water-tight or be able to hold back combustion gases from escaping past the mating surfaces.

In order to seal the block to the heads, we use a head gasket, which has several things it needs to seal against. The main thing is the combustion pressure on each cylinder. Oil and coolant must easily flow between block and head, and it is the job of the head gasket to keep these fluids from leaking out or into the combustion chamber, or into each other for that matter.

A typical head gasket is usually made of a soft sheet metal that is stamped with ridges that surround all leak points. When the head is placed on the block, the head gasket is sandwiched between them. Many bolts, called head bolts, are screwed in and tightened down, causing the head gasket to crush and form a tight seal between the block and head.

Cooling System Maintenance and Repair

An engine that is overheating will quickly self destruct, so proper maintenance of the cooling system is very important to the life of the engine and the trouble free operation of the cooling system in general.

The most important maintenance item is to flush and refill the coolant periodically. The reason for this important service is that antifreeze has a number of additives that are designed to prevent corrosion in the cooling system. This corrosion tends to accelerate when several different types of metal interact with each other, which causes scale that eventually builds up and begins to clog the thin flat tubes in the radiator and heater core—causing the engine to eventually overheat.

The anti-corrosion chemicals in the antifreeze prevents this, but they have a limited lifespan.

Newer antifreeze formulations will last for 5 years or 150,000 miles before requiring replacement. These are usually red in color and are referred to as “Extended Life” or “Long Life” antifreeze.

GM has been using this type of coolant in all their vehicles since 1996. The GM product is called “Dex-Cool”.

Most antifreeze used in vehicles, however, is green in color and should be replaced every two years or 30,000 miles, whichever comes first. You can convert to the new long life coolant, but only if you completely flush out all of the old antifreeze. If any green coolant is allowed to mix with the red coolant, you must revert to the shorter replacement cycle.

We will do a good job in every content,do our best to solve the problem for each customer,Thank you for your reading.

Leave A Comment