What if the air flow sensor fails? How to repair.

Maintenance Essentials Of Air Flow Sensor

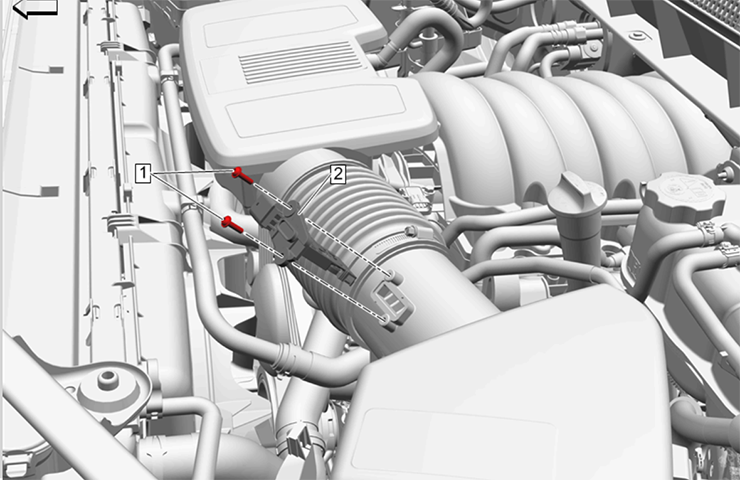

The air flow signal is one of the main signals used by the engine ECU to control the concentration of the mixture. If the amount of air intake increases, the ECU controls the amount of fuel injection, and vice versa.

Impact On Cars

Although the air flow sensor is not abnormal enough to cause the engine can not start, but it will certainly affect the engine's dynamic performance, such as idle instability, poor acceleration, intake pipe "backfire" and exhaust pipe smoke, etc., and cause excessive exhaust emissions.

(1) Cause Poor Engine Acceleration

A Passat GLi car has a driving range of 45,000 km. When the engine is accelerated to 4200r/min and the accelerator pedal is pressed, the engine speed decreases instead. It is detected by VAG1551 fault diagnosis instrument and no fault code is stored. When reading the data flow at 4200r/min, it is found that the air flow data can only reach 1.1-1.3g /s, and cannot change with the opening and closing of the throttle. After replacing the air flow sensor, the fault was removed. Find out why. The output signal of the air flow sensor was not deviated enough for the electric control Unit (ECU) to record the fault code, but because the air flow signal did not accurately reflect the actual air intake, the ECU controlled the fuel injection volume accordingly too low, so the engine speed fell rather than rose.

⑵ Lead To "Temper" Of The Intake Pipe

A Jetta King car. Engine idling jitter, rapid acceleration of the intake pipe "backfire" phenomenon. Check the intake system. No leaks found. Replace the fuel filter and clean the 4 fuel injectors. Check fuel pressure, idle and acceleration are normal. Remove the air flow sensor plug test, the fault phenomenon greatly improved. Measure the resistance of each terminal of the air flow sensor. It is normal. Dust was found on the hot film resistor of the air flow sensor. After dust accumulation was removed with carburetor cleaner, the fault was eliminated.

For the use of hot film type air flow sensor of the efI engine, it is a constant voltage in the hot film (resistance) at both ends, so that the resistance heat, its temperature controlled by the circuit. ECU determines the amount of air intake and determines the amount of fuel injection according to the current of the overheat film resistance, so as to meet the needs of different engine conditions. If dust accumulates on the hot film to form an insulating layer, when the air intake increases, its temperature changes slowly and the required current becomes smaller, and the amount of oil injection determined by ECU will decrease. At this time, the actual air intake is relatively large, leading to the mixture of too thin, and eventually lead to engine idle jitter, rapid acceleration "backfire" and other fault phenomena.

(3) The Automatic Transmission Cannot Shift Into Overdrive

If the air flow sensor shorted to the ground, it would cause the mixture to be too thin, which would reduce the engine's output power and cause the automatic transmission to be unable to shift into overdrive. The air flow sensor should be replaced.

Preliminary Judgment

Air flow sensor faults are divided into two categories. One is that the signal exceeds the specified range, indicating that the air flow sensor has failed. Modern electronic vehicles have fail-safe functions. When a sensor's signal fails, the electronic control unit (ECU) will replace it with a fixed value, or replace the faulty sensor's signal with another sensor's signal. After the air flow sensor fails. The ECU replaces it with a throttle position sensor signal. The other is signal inaccuracy (performance drift). An inaccurate air flow sensor signal can be more harmful than no signal at all. This is because. Since the signal isn't out of range. The electronic control Unit (ECU) controls the injection rate based on this inaccurate air flow signal, often resulting in a mixture that is too thin or too thick. If there is no air flow signal, the ECU uses a signal from the throttle position sensor instead, and the engine idles steadily.

By taking advantage of this characteristic, the performance of the air flow sensor can be judged by unplugging it.

①If the fault symptom does not change, the air flow sensor is damaged. This is because the ECU has replaced the throttle position sensor signal after confirming that the air flow sensor has failed. At this time, the result is the same with or without the air flow sensor, so the fault phenomenon does not change.

②If the fault phenomenon is reduced, the performance of the air flow sensor drift, signal bias. Because the air flow signal is in the effective range, the ECU controls the fuel injection volume in accordance with the distorted signal, causing obvious failure phenomena. After removing the plug of the air flow sensor, the ECU decided that the air flow sensor had completely failed and replaced it with a throttle position sensor signal, so the engine worked better.

③If the fault has worsened. The air flow sensor is normal. This is because before pulling the plug, the ECU follows the normal air flow sensor signal to control the fuel injection volume. After pulling the plug, the ECU switched to throttle position sensor signals to control the fuel injection, which was not as accurate as the former, so the failure phenomenon worsened.

In addition, since the air flow sensor signal is the main basis for controlling the air-fuel ratio, infrared tail gas analyzer can be used to measure the exhaust composition of the engine at idle speed and at the stable condition of 2000r/min. If the difference from the standard value is too large, it may be the fault caused by poor performance of the air flow sensor.

Fault Code Features

(1) After the failure of the hot film air flow sensor (G70), the electronic control unit (ECU) does not directly give the fault code of the air flow sensor, but shows it through other fault codes, usually "00561" (the adjustment value of mixed steam exceeds the adjustment limit) or "17916" (reaching the theoretical limit of idle speed adjustment system).

(2) The fault code of the air flow sensor may be recorded when other parts of the engine are abnormal. In maintenance practice, the following situations are common to record the fault code of air flow sensor.

①The throttle is dirty, which may record the fault code of the air flow sensor. A Bora 1.8T sedan. In normal driving. Sometimes the ASR (Drive anti-skid control) light on the instrument panel suddenly lights up, and pressing the ASR light switch is ineffective. The ASR light will only go off when the ignition switch is turned off and the engine is restarted. Connect the fault diagnosis instrument VAS5051 for detection, and read out the fault information of "the signal value of air flow sensor G70 displayed in the engine system is too small". Check that the resistance of each G70 terminal is less than 1.5 OHms. Check the G70 waveform. Normal. Replacement of G70, void. The vehicle adopts can-bus multi-channel information transmission system. ABS/ASR control unit communicates with engine control unit through CAN-bus. On the one hand, when the throttle body is dirty, the opening value of the throttle increases, but the actual air intake does not increase. As a result, the signal of G70 does not match the opening of the throttle, so the fault information of "G70 signal value of the air flow sensor displayed in the engine system is too small" is recorded. On the other hand, the ASR system implements drive anti-skid control by reducing the engine speed to adjust the output torque of the engine. Therefore, although the fault phenomenon is manifested in the braking system, the root of the fault is in the engine. When there is a deviation between the throttle opening signal and the air flow signal (the throttle opening is large, while the actual air intake measured by G70 is small), the ABS/ASR control unit thinks that the engine has reduced the power output and is carrying out drive anti-skid control, so it lights the ASR indicator.

②Throttle position sensor performance is abnormal, may record the fault code of the air flow sensor. A Jetta sedan was detected with a fault diagnosis instrument and read the fault code of the unreasonable signal of the air flow sensor. Replacing the air flow sensor didn't work. The so-called "unreasonable" is compared with the signal of the relevant sensor. In fact, the ECU determines engine load by comparing engine speed and throttle position signals with air flow signals. Further inspection of the throttle position sensor found that the maximum and minimum learning values were inconsistent with the specified values, and basic Settings could not be carried out. After replacing the throttle assembly (including throttle position sensor) and performing basic Settings, the fault was eliminated.

③The oxygen sensor is damaged and may record the fault code of the air flow sensor. When the oxygen sensor of Jetta king car is damaged, it will remember the fault code of the air flow sensor. Its principle is that fuel combustion is not complete due to the "lack of cylinder" and other reasons, beyond the adjustment range of λ, resulting in the signal of the oxygen sensor is not accurate, so the engine ECU keeps adjusting back and forth between the mixture of too thin and too thick. The air flow signal received by the ECU contradicts the oxygen sensor signal. But from the practical effect, oxygen sensor damage can not adjust λ and air flow sensor signal serious drift is the same, ECU in accordance with the principle of priority, then memory air flow sensor fault code.

Data Flow Analysis

(1)The unit and range of air flow sensor signal parameters depend on the type of air flow sensor. The parameter unit of the wing-plate, hot-wire and hot-film air flow sensors is "V" and ranges from 0 to 5V. The value of this parameter is inversely proportional to the air intake, that is, when the air intake increases, the output voltage decreases, and "5V" indicates the minimum air intake. "0V" indicates the maximum air intake.

The unit of signal parameter of eddy current air flow sensor is "Hz" or "ms", and its range is 0 ~ 1600Hz or 0 ~ 625ms. The value ranges from 25 to 50Hz at idle speed and from 70 to 100Hz at 2000r/min. If the value under different working conditions differs greatly from the standard value or there is no change. The air flow sensor is faulty.

(2)By analyzing the data flow of air flow sensor, we can judge whether the air leakage exists in the engine intake system. Under normal conditions, idle air flow signal data is about 2.5g/s. If less than 2.0g/s, it indicates that there is air leakage in the intake system; if more than 4.0g/s, it indicates that there is extra load in the engine.

An Audi A6 1.8T car is equipped with a manual transmission, which shakes every 2 to 3 minutes when the engine is running. But the engine started and accelerated normally. Connect the fault diagnosis instrument VAS5052, enter 01-08-02, and read the data flow. The air flow data displayed in zone 4 is in the range of 0.3-3.5g /s with frequent periodic pulsation. The inspection found. The clamp at the lower part of the connection between the air filter housing and the intake hose is not properly installed, resulting in air leakage. After handling the air leakage. Troubleshooting.

(3)In the detection process, maintenance personnel will find that after the air flow sensor is disconnected, the air flow data can still be seen in the data stream, and it is in the normal range, and the response to rapid acceleration is sensitive. It is actually the fault operation mode of the control system, and is the backup data of air flow given by the engine ECU according to signals such as speed and load.

Key Points Of Air Flow Sensor Maintenance

(1) Hot Wire And Hot Film After Dirty Cleaning

If the engine has a "backfire" fault, it often causes serious harm to the air flow sensor. Because the engine air flow in the intake manifold reverse flow (namely "temper"), which contains carbon particles, these carbon particles easily adhere to the air flow sensor sensor sensor sensor, and produce the following consequences: in idle speed, the air flow sensor signal is too large, and in acceleration and large load signal is too small.

To check whether the hotline has self-cleaning ability, remove the air filter and check the hotline from the air inlet of the air flow sensor. If the hotline does not emit a slight red glow for about 1s after the engine is turned off for 5s, it indicates that the self-cleaning ability of the hotline has been lost.

Hot wire (hot film) can be polluted in the heat engine, idle state. Remove the filter screen of the air filter, and use the carburetor cleaner to spray the hot wire or hot film directly to remove the carbon accumulation attached to it.

(2)The Treatment Of Hot Film Air Flow Sensor After Damage

Many models use the hot film air flow sensor produced by BOSCH company, its core part is composed of an integrated circuit (d/A conversion circuit) and Wheatstone bridge, no voltage regulator circuit. Therefore, when the supply voltage is too high or instantaneous high voltage, the hot film air flow sensor is easy to burn out. And the circuit peak voltage is too high (more than 16V), often is the battery vulcanization is serious, so that its capacity decreases, unable to absorb the peak voltage of the generator, so the battery vulcanization is one of the reasons for the damage of the hot film air flow sensor. The solution is to install a 7812 three-terminal regulated integrated circuit in the front end of the hot film air flow sensor.

(3) Blocked Air Does Not Pass Through The Metering Access

These include broken intake lines, loose vacuum hoses, and loose seals between intake manifold and cylinder head. If the above situation exists. Part of the air will not pass through the air flow sensor measurement and directly into the cylinder, resulting in engine mixed steam imbalance.

(4) The Substitution Problem Of Air Flow Sensor Damage In Public Vehicles

The air flow sensor in Volkswagen cars is a fault - prone component. After the air flow sensor is damaged, if the original parts can not be found for a while, it is faced with the problem of universal exchange of parts. If the engine is installed with a different type of air flow sensor, it will make the injection volume control is not accurate. In the open-loop control stage, the fuel consumption of the engine may increase and the temperature of the three-way catalytic converter is too high. In the closed-loop control stage, the oxygen sensor will constantly modify the concentration of the mixture of steam, so that the air-fuel ratio changes frequently, resulting in unstable engine operation.

We will do a good job in every content,do our best to solve the problem for each customer,Thank you for your reading.

Leave A Comment