What is the use of an oil pan for a car engine?

The oil sump is the lower half of the crankcase, also known as the lower crankcase. The function is to close the crankcase as the shell of the oil storage tank, prevent impurities from entering, and collect and store the lubricating oil flowing back from the friction surface of the diesel engine, dissipate part of the heat, prevent the oxidation of lubricating oil.

Introduction Of Oil Pan

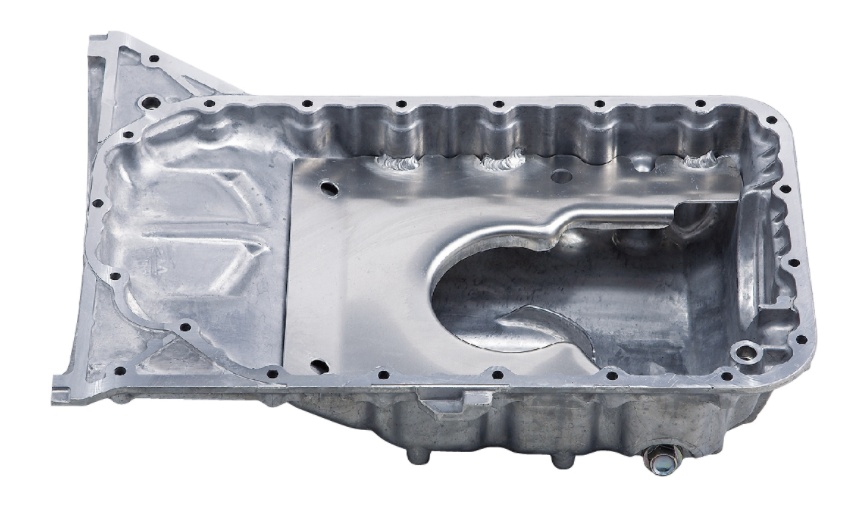

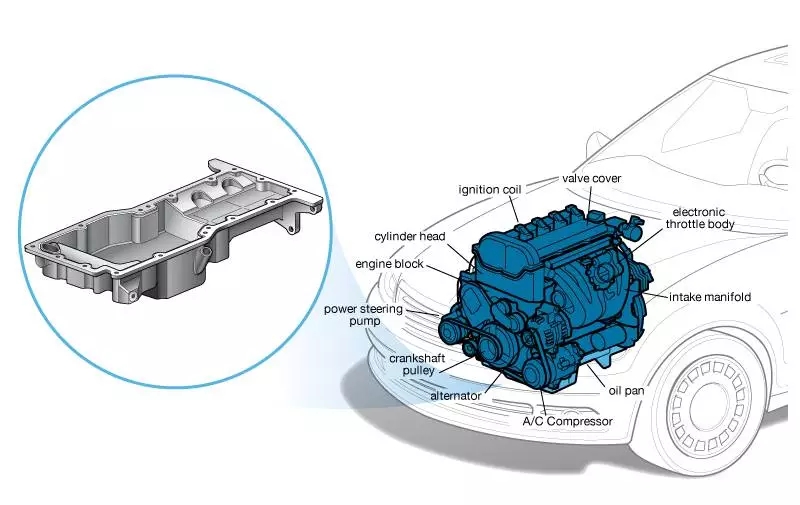

The Oil Pan is located under the engine: it is detachable and seals the crankcase as an Oil tank housing. The oil pan is mostly made of thin steel plate, and the more complex shape is generally cast by cast iron or aluminum alloy. Its internal oil stable baffle, in order to avoid diesel engine turbulence caused by the oil surface shock splash, is conducive to the precipitation of lubricating oil impurities, side is equipped with a dipstick, used to check the amount of oil. In addition, the bottom of the oil pan is equipped with the lowest drain plug.

Classification Of Oil Pan

Wet Type

See most of the cars on the market are wet sump, was named the wet sump is due to the engine crankshaft crank and connecting rod head in crankshaft every once immersed within the lubricating oil sump, lubrication effect, at the same time due to the high speed of the crankshaft, crank every high-speed immersion oil pool has certain spray and oil mist, The lubrication of crankshaft and bearing bush is called splash lubrication. In this way, there are certain requirements for the liquid level height of the lubricating oil in the oil pan. If it is too low, the crank and the big head of the connecting rod can not be immersed in the lubricating oil, resulting in the lack of lubrication and smooth crankshaft, connecting rod and bearing bush; If the lubricating oil level is too high, it will lead to the whole bearing immersion, increase the rotary resistance of the crankshaft, and eventually lead to the decline of engine performance. At the same time, the lubricating oil is easy to enter the combustion chamber of the cylinder, resulting in engine oil burning, spark plug carbon accumulation and other problems.

This lubrication mode is simple in structure and does not need to set up another fuel tank, but the inclination of the vehicle work can not be too large, otherwise it will cause burning walla cylinder accident due to oil breakage and oil leakage.

Dry Type

A dry sump is used in many racing engines. It stores no oil in the sump, or rather, no sump. The friction surfaces of these movements in the crankcase are lubricated by pressing oil out of a single hole. Since the dry pan engine eliminates the oil storage function of the oil pan, the height of the oil pan is greatly reduced, and so is the height of the engine. The benefit of the reduced center of gravity is better handling. The main advantage of the wet sump is that it avoids the adverse effects of intense driving.

However, because the pressure of lubricating oil all comes from the oil pump. Oil pump power is through the rotation of the crankshaft through the gear connection. In a wet sump engine an oil pump is also required to provide pressure lubrication for the camshaft. But the pressure is small and the pump requires very little power. In a dry sump engine, however, the strength of this pressure lubrication is much greater. The size of the oil pump is also much larger than that of a wet sump engine. So the pump needs more power at this point. As with a supercharged engine, the pump consumes part of the engine's power. Especially at high speed, when the engine speed increases, the motion strength of friction parts increases, and the oil for lubrication is also more, so the oil pump is needed to provide greater pressure, and the consumption of crankshaft power is intensified.

Obviously, this design is not suitable for ordinary civil car engine, because it needs to lose part of the engine power, not only will affect the power output, but also is not conducive to improving the economy. So dry sumps are only used on large or powerful engines, such as those built for intense driving in sports cars. Lamborghini, for example, adopts the design of dry sump. For lamborghini, it is more important to improve the lubrication effect at the limit and obtain a lower center of gravity. The loss of power can be made up for by increasing displacement and other aspects.

Oil Pan Operation And Maintenance

Fuel injection pump is an important part of diesel generator fuel supply system. Its working condition directly affects the power performance, economy and reliability of diesel generator. Correct maintenance is an important prerequisite to ensure the normal operation of fuel injection pump and prolong its service life. The following "ten essentials" will teach you how to maintain a diesel generator fuel injection pump:

1.To Correctly Maintain The Accessories Of The Fuel Injection Pump.

Pump body side cover, dipstick, refueling plug (breathing apparatus), oil spill valve, oil pool screw plug, oil plane screw, oil pump fixing bolt, etc., to ensure intact, these accessories play a vital role in the work of the fuel injection pump. For example, the side cover can prevent the invasion of dust, water and other impurities, the respirator (with filter screen) can effectively prevent oil deterioration, and the oil spill valve ensures that the fuel system has a certain pressure and does not enter the air. Therefore, it is necessary to strengthen the maintenance of these accessories, found damaged or lost to timely repair or replacement.

2. Often Check The Amount Of Oil In The Oil Pool Of The Fuel Injection Pump And Whether Its Quality Meets The Requirements.

Before every start diesel generator should check inside the fuel injection pump oil quantity and the quality of the (except on engine fuel injection pump of forced lubrication), to ensure that the oil amount is enough, the quality is good, if the oil mixed with water or diesel and metamorphism, light person plunger and delivery valve couple early wear, causing shortages of diesel engine power start is difficult, When it is serious, the plunger and the oil valve couple will be corroded and corroded. Due to the leakage in oil pump, the oil valve working poor, oil transfer pump wear, sealing ring is damaged, tappet and shell will make diesel oil leakage into the pool and dilute oil, so should be according to the quality of the oil change in time, when you change to thoroughly clean the oil pool, the oil of the bottom sludge impurities such as clean, or use oil for a long time and goes bad. The number of oil can not be too much or too little, too much oil in the governor, easy to lead to diesel engine "flying", too little oil will make poor lubrication, should be based on oil ruler or oil plane screw. In addition, when the diesel engine is not used for a long time, it is necessary to check whether there is water, diesel and other impurities in the oil pool of the oil pump. If there is, it should be replaced immediately. Otherwise, due to long-term storage, water can easily make the plunger and oil outlet valve parts rust and scrap.

3. To Regularly Check And Adjust The Oil Supply Of Each Cylinder Of The Fuel Injection Pump.

Due to the wear and tear of the plunger and the oil valve, the diesel oil leakage will reduce or uneven the oil supply of each cylinder, resulting in the difficulty of starting the diesel engine, insufficient power, increased oil consumption and unstable operation. Therefore, it is necessary to regularly check and adjust the fuel supply of each cylinder of the injection pump to ensure the play of diesel engine power. In practical use, we can determine the size of the fuel supply of each cylinder by observing the smoke exhaust of the diesel generator, listening to the engine sound, feeling the exhaust manifold temperature and other methods.

4.To Use Standard High Pressure Tubing.

In the process of the fuel injection pump in oil supply, due to the compressibility of diesel, high pressure tubing elasticity, high pressure diesel will be formed in the pipe pressure fluctuations, it takes time to pressure wave in tube, to ensure that each cylinder injection interval Angle is consistent, uniform oil, diesel engine work smoothly, high pressure tubing length and diameter is calculated and selected. Therefore, when the high-pressure tubing of a cylinder is damaged, the tubing of standard length and diameter should be replaced. In actual use, due to the lack of standard tubing, with other tubing alternative, regardless of the tubing is the same length, diameter, length and diameter of tubing vary widely, although can be used in emergency, but will result in the fuel delivery advance Angle of the cylinder and oil changes, cause the machine work is not smooth, so be sure to use standard in use of high pressure oil pipe.

5.To Check The Sealing Of Valve Parts On a Regular Basis.

Fuel injection pump work for a period of time, through checking the sealing of the oil valve can make a rough judgment of the wear of the plunger and the work of the oil pump, so as to determine the repair and maintenance method. Check, unscrew the cylinder high-pressure hose connector, in the hand of oil transfer pump pump pump oil, so they found fuel injection pump at the top of the tubing connectors have oil flow out, also shows that the oil valve seal bad (such as the oil valve spring break, of course, also can appear this kind of situation), such as multi cylinder appear seal undesirable phenomenon, should be made for fuel injection pump to complete debugging and maintenance, change the matching parts.

6. To Replace The Wear Of The Plunger And Oil Valve Parts In Time.

When it is found that the diesel engine is difficult to start, power decline and fuel consumption increase, and the injection pump and injector are still not improved by adjusting, the injection pump plunger and oil outlet valve couple should be removed and checked. If the plunger and oil outlet valve are worn to a certain extent, they should be replaced in time and do not insist on reuse. Due to the loss of diesel engine starting difficulty, fuel consumption increase and power shortage caused by the wear of the parts far exceeds the cost of replacing the parts, the power and economy of the diesel engine will be significantly improved after the replacement, so it is necessary to replace the worn parts in time.

7. To Good Use And Filtration Of Diesel Oil, Ensure That The Diesel Oil Into The Fuel Injection Pump Is Highly Clean.

Generally speaking, the filter requirements of diesel oil of diesel generator are much higher than the requirements of gasoline engine. When using diesel, it should meet the requirements of diesel, and at least after 48h precipitation. To strengthen the cleaning and maintenance of diesel filters, timely cleaning or replacement of filter elements; According to the operating environment conditions, the diesel tank should be cleaned in time to thoroughly remove the oil sludge and moisture at the bottom of the tank. Any impurities in the diesel oil will cause serious corrosion or wear to the plunger of the fuel injection pump, the coupling of the oil outlet valve and the transmission parts.

8.Check And Adjust The Oil Advance Angle Of The Fuel Injection Pump And The Oil Interval Angle Of Each Cylinder Regularly.

In use, due to the loosening of the coupling bolt, camshaft and roller body parts wear, often lead to oil supply in advance Angle and each cylinder oil supply interval Angle change, so that diesel combustion is bad, the power of the diesel engine, the economy is poor, at the same time difficult to start, unstable operation, abnormal sound and overheating. In be used actually, most drivers pay attention to the overall inspection adjustment of fuel supply advance Angle, but neglected the oil supply interval Angle of single pump fuel supply advance Angle adjustment) (relating to the inspection, cause the overall adjusted while the first cylinder injection timing, but the rest each cylinder due to the camshaft, partly due to the wear of wheel driving part make the oil supply is not necessarily timing, It will also lead to diesel engine starting difficulties, insufficient power, unstable operation, especially for the use of a longer time injection pump, more attention should be paid to the inspection and adjustment of oil supply interval Angle.

9.To Check The Camshaft Clearance Regularly.

The axial clearance requirements of the injection pump camshaft are very strict, generally between 0.03 ~ 0.15mm, the clearance is too large, will intensify the impact of the roller drive components on the CAM working surface, thus increasing the early wear of the CAM surface, change the oil supply in advance Angle; Camshaft bearing shaft, diameter clearance is too large, easy to cause the camshaft operation is not smooth, oil adjustment rod jitter, oil supply changes periodically, so that the diesel engine is not smooth, so it should be checked and adjusted regularly. When the axial clearance of the camshaft is too large, gaskets can be added on both sides to adjust the radial clearance is too large, and it is generally necessary to replace the new product.

10. The Wear And Tear Of Relevant Keyway And Fixing Bolt Should Be Checked Regularly.

Related keyways and bolts mainly refer to camshaft keyways, coupling flange keyways (oil pumps with power transmission by coupling), semicircular keys and coupling fixing bolts. Oil injection pump camshaft keyway, flange keyway, semicircle key due to long-term use, light wear, so that the keyway becomes wider, semicircle key installation is not firm, oil supply advance Angle changes; Heavy keys fall, resulting in power transmission failure, so it is necessary to check regularly, repair or replace the worn parts in time.

Matters Needing Attention

Diesel Incentive

1. O-ring of fuel injector is damaged;

2. The injector atomization is bad, oil drops;

3. Improper installation of fuel injector;

4. The fuel injector is not replaced with a new O-ring when it is re-installed.

Cummins Generator Storage Should Be Noted:

1) The storage position of the fuel tank must be safe to prevent fire. The fuel tank or oil barrel should be placed separately in a visible place, appropriately far away from the diesel generator set, and smoking is strictly prohibited.

2) The fuel capacity in the tank should ensure daily supply.

3) After the tank is placed, the highest oil level should not be 2.5 meters higher than the base of the diesel generator set. If the oil level of the large oil depot is higher than 2.5 meters, daily oil tank should be added between the large oil depot and the unit, so that the pressure of direct oil delivery is not more than 2.5 meters. Even when the diesel engine is shut down, fuel is not allowed to flow into the diesel engine through the intake line or the injection line, relying on gravity.

4) The resistance at the oil opening is not allowed to exceed the specified value of clean filter element specified on the performance data sheet of all diesel engines. This resistance value is based on the fuel tank being half filled with fuel.

5) fuel return resistance can not exceed the provisions of the diesel engine performance data sheet.

6) The connection of fuel return pipeline should not cause shock wave of fuel in the pipeline.

We will do a good job in every content,do our best to solve the problem for each customer,Thank you for your reading.

Leave A Comment