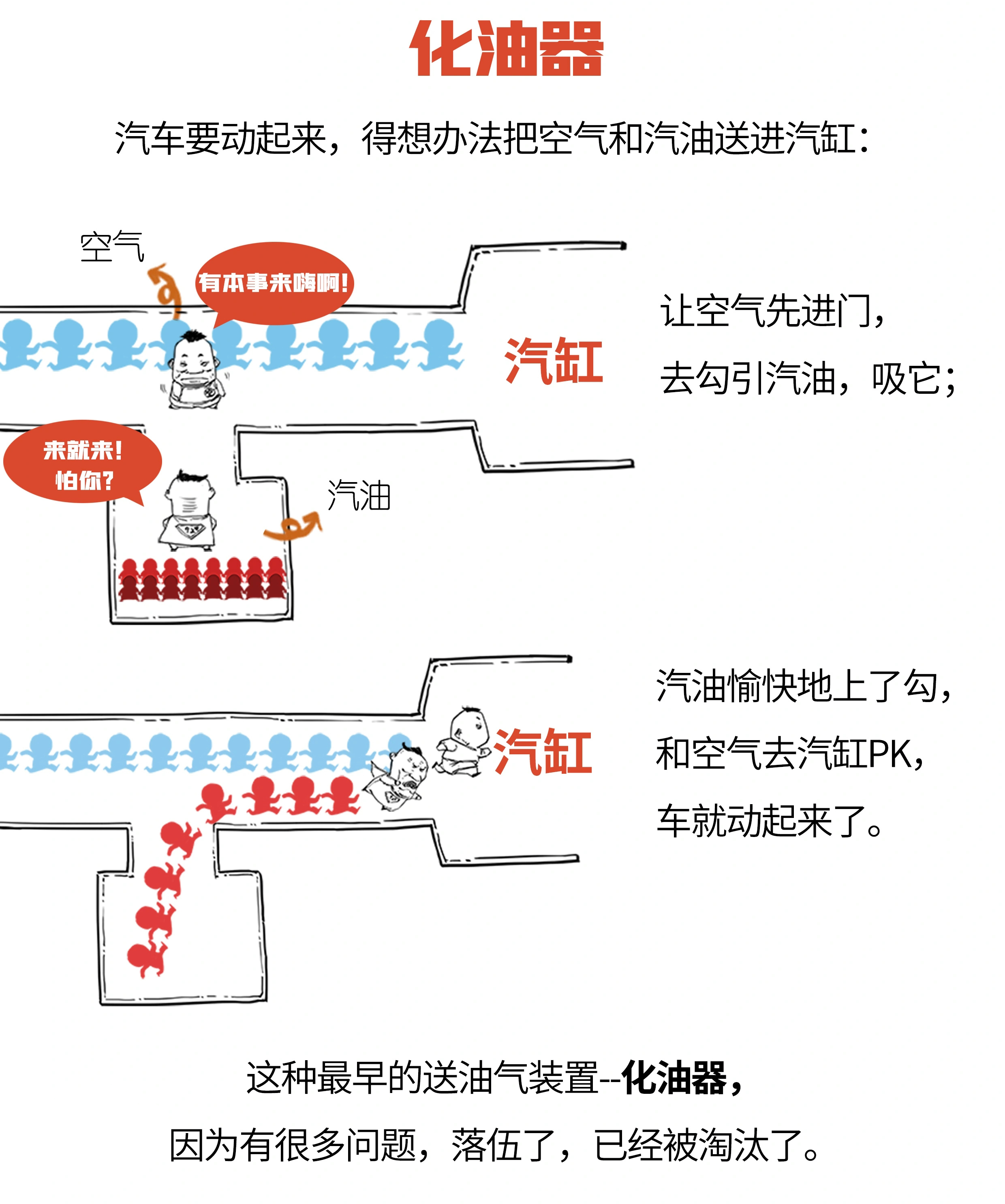

What does a carburetor do for an engine?

Carburetor is a mechanical device that mixes a certain proportion of gasoline and air under the vacuum created by the engine. Carburetor as a precise mechanical device, it uses the kinetic energy of the inhaled air flow to achieve gasoline atomization. Its important role in the engine can be called the "heart" of the engine. The complete device shall include starting device, idle device, medium load device, full load device and acceleration device. Carburetor according to the requirements of different working conditions of the engine, automatic matching of the corresponding concentration, the output of the corresponding amount of mixture, in order to make the distribution of the mixture of more uniform, carburetor also has the effect of fuel atomization, for the normal operation of the machine.

The Main Classification

Carburetors are divided into simple carburetors and complex carburetors. Carburetor can also be divided into lower suction and flat suction. Carburetor from the type of throttle points, and can be divided into rotation and lifting type. Rotational throttle is a disk-shaped throttle that rotates around an axis between the carburetor throat tube and the intake pipe to change the flow area of the inlet. The structure of the lifting type throttle is a barrel form plate throttle, which moves up and down at the throat tube to change the channel area at the throat tube. Motorcycle carburetor is mostly in this form. Another carburetor is a hybrid of the two, with a rotating throttle controlled by a man and a lifting throttle controlled by a diaphragm. This is also commonly used on motorcycles and is called the CV.

The Basic Structure

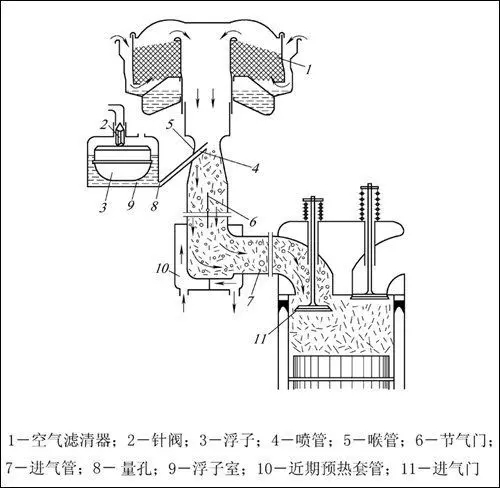

A simple carburetor is composed of three parts, the upper part of the air inlet and float chamber, the middle part of the throat, orifice and nozzle, the lower part of the valve and so on. The float chamber is a rectangular container that stores gasoline from the gasoline pump. Inside the container, a float controls the amount of oil that comes in using the height of the float (oil surface). The middle nozzle inlet is connected with the measuring hole of the float chamber, and the oil outlet is at the throat of the throat tube.

The laryngeal tube is a bee waist shaped, large at both ends and small in the middle, among which the throat has the smallest cross-sectional area. When the engine is started, the piston produces suction downward, and the suction airflow passes through the throat at the maximum speed, but the static pressure is the lowest, so the throat pressure is less than the atmospheric pressure, that is to say, there is a pressure difference between the throat and the float chamber, which is often called "vacuum degree", and the greater the pressure difference, the greater the vacuum degree. Gasoline under the action of vacuum from the nozzle out of the oil mouth, because the flow of air at the throat of the throat is 25 times the flow of gasoline, so the nozzle out of the oil flow is dispersed by high-speed air flow, the formation of different sizes of fog particles, that is, "atomization". The initial atomized oil particles are mixed with the air into a "mixture" that passes through the throttle, intake pipe and intake valve into the cylinder's combustion chamber. Here, the valve opening size and engine speed determine the vacuum degree at the throat, and the throttle opening changes directly affect the mixture proportion, which are important reasons affecting the engine operation.

Here involves a "air-fuel ratio" concept, the air-fuel ratio is the ratio of air and fuel quality, scientists believe that the 1 kg of gasoline combustion takes about 14.7 kg air, namely the air-fuel ratio was 14.7:1, the air-fuel ratio of mixture called standard mixture, because this value is hard to realize in practice, so also known as the "theory of mixture". Air - fuel ratio greater than the standard mixture is called thin mixture, less than the standard mixture is called thick mixture.

Because the change of mixture concentration is closely related to the change of engine load under various operating conditions, the simple carburetor is far from meeting the requirement of changing at any time, so new devices are constantly added to the simple carburetor to adjust the working state of the carburetor. Today, carburetors have been developed with various auxiliary devices, mainly idle, enrichment, acceleration and starting devices. At present, the common carburetor of 4-cylinder engine is the double-cavity split moving carburetor, which has two pipes and works separately or simultaneously according to different working conditions of the engine. The common carburetor for 6-cylinder engines is the double-chamber parallel carburetor, which is actually two single-chamber carburetors together, each chamber responsible for half the number of cylinder mixture gas supply. There are also multi-chamber carburetors, which are usually fitted to more powerful engines.

Among the various functional devices of the carburetor, the main fuel supply device is the basic fuel supply structure of the carburetor, which is required by all other working conditions except idle speed. Idle gear is a device that provides a small but thick mixture of air during idle operation to maintain a stable minimum engine RPM. The thickening device is an extra fuel supply device when the engine is under heavy load to make up for the shortage of the main fuel supply. Acceleration device is an extra fuel supply device when the valve opening suddenly increases when the car accelerates, so that the engine speed and power can increase rapidly. The starter is a device that provides a very thick mixture of air when the engine is started cold, usually by installing a choke in front of the throat to control the intake volume.

Idle is a special mention here. Idling is the most commonly used engine condition, which is used in the process of engine thermal start and non-stop stop. It is of great significance to the vehicle driving performance, especially in the city, idling speed often determines the fuel consumption and pollution level of the vehicle driving.

Engine idling speed is usually only 600-800 RPM and the throttle is close to closing. The vacuum created by this speed is not able to pull gasoline out of the float chamber, but the vacuum behind the throttle is very high. Therefore, only on the basis of the simple carburetor, another idle oil channel, its jet hole is set in the throttle, the problem will be solved.

Because the idle speed needs less and thick mixture, it is sensitive to the engine running condition, so it is necessary to adjust the fuel quantity control and the throttle minimum opening to achieve the idle speed state of both stability and minimum speed. The current carburetor idle device has two adjusting screws that adjust the fuel volume and throttle opening respectively. At the same time, in order to prevent the car to close the ignition switch and the engine is still running phenomenon, in the carburetor idle oil channel is also equipped with idle solenoid valve, specially responsible for opening and cut-off idle oil channel, to ensure that the engine can quickly flameout.

The Working Principle Of

The carburetor is essentially a tube with an adjustable plate in the middle called a throttle plate that controls the flow of air through the tube. The tube has a shrinking part called the venturi tube, where a vacuum is formed. This shrinkage part has a measuring hole through which the fuel can be sucked in by vacuum.

Motorcycle carburetors look very complicated, but with a few principles, you can tune your motorcycle to optimum condition. All carburetors operate on the basic principle of atmospheric pressure. Atmospheric pressure is a powerful force that exerts pressure on everything. It varies slightly, but it's usually about 15 PSI per square inch. That means atmospheric pressure on everything is 15 pounds per square inch. By changing the atmospheric pressure in the engine and carburetor, you can change the pressure and allow fuel and air to flow through the carburetor.

Atmospheric pressure diffuses from high to low. When the piston of a two-stroke engine is at BDC (or the piston of a four-stroke engine is at BDC), a low pressure forms under the piston in the crankcase (above the piston of a four-stroke engine). This low pressure also causes low pressure in the carburetor. Because the pressure outside the engine and carburetor is high, air will rush into the carburetor and into the engine until the pressure equalizes. Air flowing through the carburetor will drive the fuel, which will then mix with the air.

Inside the carburetor is a tube. The throat is the constricted part of the carburetor that forces air to accelerate through. A sudden narrowing of the river can be used to illustrate what happens inside the carburetor. The river speeds up as it approaches a narrowing bank, and even faster if the bank continues to narrow. If the same thing happens in a carburetor, the accelerated flow of air will cause the pressure inside the carburetor to drop.

Gasoline enters the carburetor from the tank through a gasoline filter, which filters out impurities in the gasoline and the oxide scale in the tank. If the filter quality is defective, there is still some impurities through the filter into the carburetor. In addition, gasoline contains colloidal components, after a long time of deposition will condense colloidal, attached to the carburetor parts (such as holes), oil passage and float chamber surface.

Air is through the air filter into the carburetor, based on the intake resistance can not be too large and other factors, the filter device can not be too dense, so part of the small impurities in the air will still enter the carburetor through the air filter. If the quality of the filter is defective, it will cause more serious effects.

In the airways of the carburetor oil duct, more spare parts, such as the main measure holes, idle hole, primary air quantity, amount of idle air hole and main foam pipe and so on all have inside a small hole (diameter between 0.3 ~ 1.5 mm), into the carburetor petrol impurity, colloid and impurities in the air, often will change the aperture or congestion, The result is that the carburetor airways and oil channels are not smooth, so that the carburetor oil supply characteristics change, and even cause the carburetor performance failure.

We will do a good job in every content,do our best to solve the problem for each customer,Thank you for your reading.

Leave A Comment