How many solenoid valves does a car have? Introduction to the application of solenoid valve in automatic transmission.

When it comes to automatic transmission, its driving convenience, power and comfort are more and more recognized by consumers, and the working principle and parts of automatic transmission are also more concerned. Today we will introduce the application of solenoid valve products in automatic transmission.

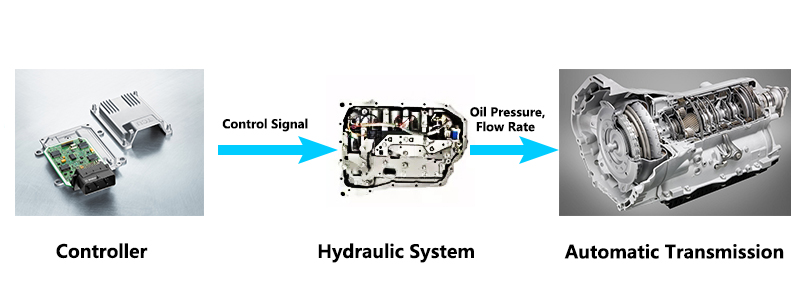

Hydraulic system and solenoid valve in automatic transmission

Whether DCT, AT or CVT transmission, the mainstream technical solution is not without hydraulic system. The hydraulic system receives the signal of the controller, outputs the oil pressure or flow, and acts on the actuator. The role of hydraulic system mainly includes: control clutch, synchronizer or pulley to achieve the change of transmission ratio, control the state of hydraulic torque converter clutch, control system cooling lubrication. Hydraulic system performance directly affects the vehicle shift comfort and fuel economy, is an important part of automatic transmission.

In the hydraulic system, the solenoid valve as the actuator, to achieve the transformation of electrical signals to hydraulic signals, control the pressure in the hydraulic system, flow, is the key parts of the hydraulic system.

Classification And Application Of Automobile Solenoid Valve

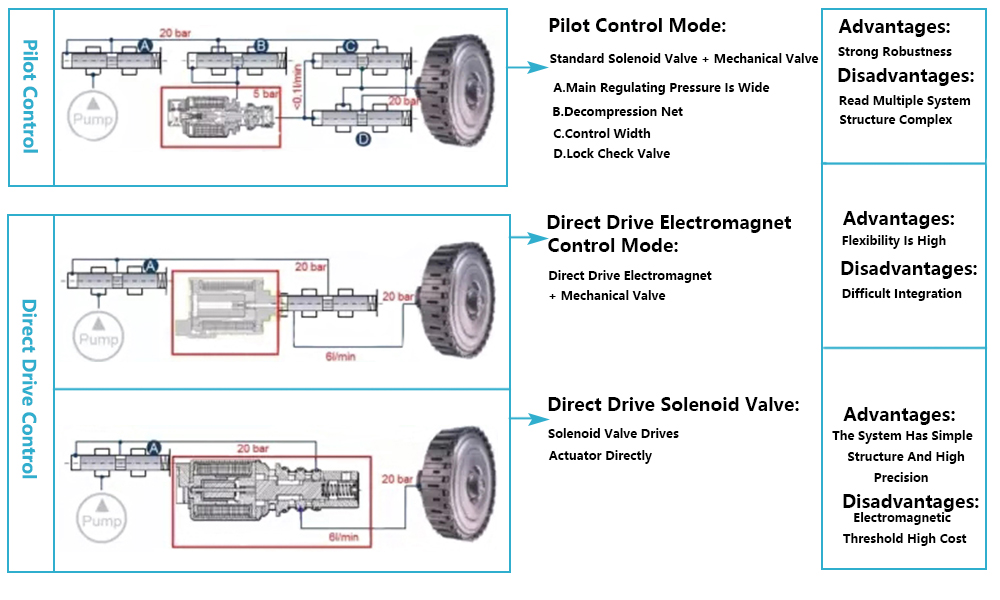

Solenoid valve in the hydraulic system is divided into pilot control and direct drive control, pilot solenoid valve control pressure and flow are relatively low, can not directly drive the actuator, only provide pilot control pressure. Direct drive solenoid valve than pilot valve has greater electromagnetic force, control pressure and flow can directly drive the actuator. The hydraulic system using direct drive solenoid valve reduces the number of mechanical valves and simplifies the system structure. Another solenoid valve product is proportional electromagnet, compared with other solenoid valves, proportional electromagnet only electromagnetic part, providing electromagnetic force, hydraulic part integrated in the hydraulic valve body, hydraulic part according to the needs of the specific system by the customer design, higher flexibility, but at the same time increased the difficulty of hydraulic system integration.

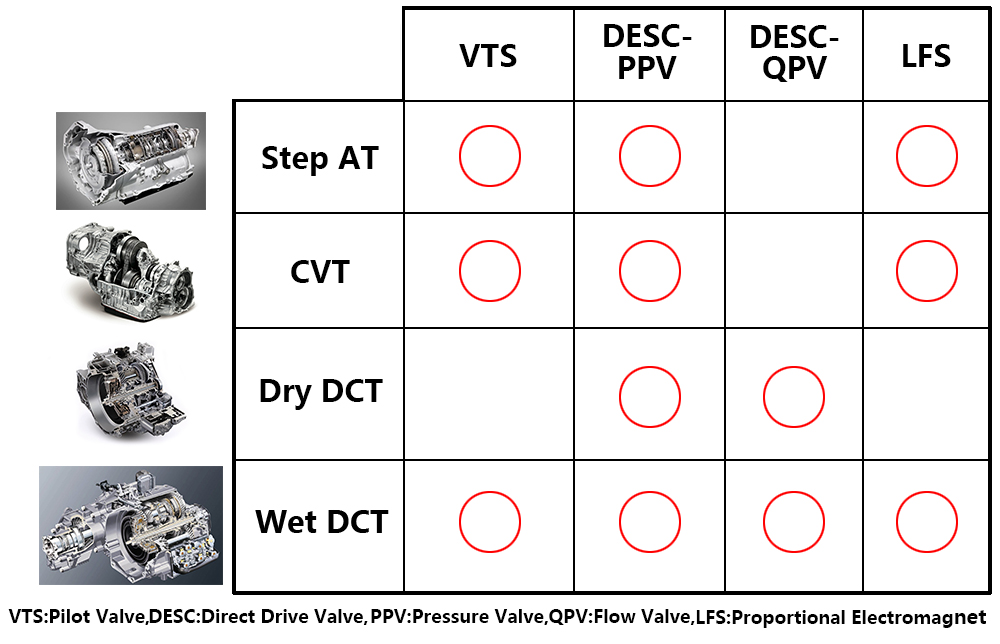

The application of different types of solenoid valves in various types of transmissions can be summarized in the following table:

Introduction To The Principle Of Joint Electronic Solenoid Valve

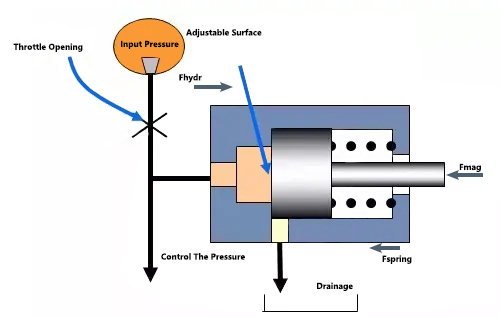

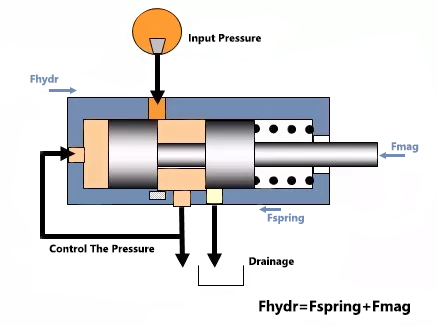

Pressure Valve Principle Introduction:

Bleed type valve: as shown below, the valve core is affected by liquid pressure, spring force and electromagnetic force. The balance state determines the position of the valve core, thus determining the area of the oil discharge port. The pressure of the left control chamber depends on the area of the Bleed port determined by the input pressure, the input cut-off port and the variable regulating surface, so Bleed valve controls the electromagnetic force to achieve the effect of pressure control. Because Bleed valve regulates pressure through overflow, it has a large leakage volume and the control pressure is sensitive to fluctuations in input pressure.

Spool Pressure Valve:

As shown in the figure below, the spool of the pressure valve is under the action of spring force, electromagnetic force and hydraulic feedback force, ignoring the influence of hydraulic force. In a stable state, the spool is in a balanced state. The electromagnetic force is positively correlated with the control current of the solenoid valve. Since the spring's properties are fixed, at equilibrium, the electromagnetic force determines the output pressure. Therefore, the solenoid valve converts the current signal into a pressure signal.

Flow Valve Principle Introduction:

Flow valve spool only by electromagnetic force and spring force, the balance of the two, determine the balance position of the spool, so as to determine the throttle area from the input to the control mouth, according to the flow formula, under the condition of a certain pressure difference, the flow of the solenoid valve is proportional to the throttle area, so the flow is proportional to the control current.

Product Classification And Application Of United Electronic Solenoid Valve

The Current Solenoid Valve Products Of United Electronics Are As Follows:

1.Constant Low/Constant High Direct Drive Pressure Control Valve (Desc-Ppv-Nl/Nh)

Direct drive proportional pressure valve, because the flow and pressure are relatively large, direct drive valve is directly used to drive the clutch and other actuators, or control the pipeline pressure in the system. The product has been used in hydraulic system of DCT, AT and CVT for clutch control, main oil pressure control and synchronizer pressure control.

Control pressure range: 0~20Bar, flow: > 10L/min, control current: 0~1.5A

2.Direct Drive Flow Control Valve (Desc-Qpv)

Flow valve is used in DCT hydraulic system, synchronizer displacement control.

Traffic: & gt; 7L/min, control current: 0~1.5A

3. Often Low/Often High Pilot Pressure Control Solenoid Valve (Vts-Nl/Nh)

Spool pilot pressure valve provides pilot control pressure for hydraulic systems of AT, CVT and DCT.

Control pressure 0~12Bar, current range 0~ 1.2a

4. Proportional Electromagnet (LFS)

Proportional electromagnetic force for mechanical valves, applications with DCT, AT, CVT.

Current range 0~1.5A, maximum electromagnetic force 20N

The combined electronic solenoid valve introduced above is a batch production product with a total annual output of more than 10 million. United Electronics has complete development and testing capabilities, and has accumulated rich practical application and problem solving experience, in addition to providing mature and reliable solenoid valve products, but also to provide comprehensive technical support for customer development process.

We will do a good job in every content,do our best to solve the problem for each customer,Thank you for your reading.

Leave A Comment